Don’t just trust - know your

supplier before committing

Before signing with a supplier, it's crucial to ensure they can truly meet your expectations. With DocShipper, our teams travel directly onsite, whether in Asia, Europe, Africa or elsewhere, to verify the reliability, compliance, and production capacity of your partners.

What can go wrong without a supplier audit

International sourcing isn’t just about finding a factory online and placing an order. Behind every supplier, there can be hidden issues that only surface once problems arise. Here’s why conducting a supplier audit before committing is absolutely essential.

Unreliable or Nonexistent Suppliers

Many so-called manufacturers are actually brokers or, in some cases, outright scams. Without a physical onsite inspection, you have no way to verify if the factory exists or if it truly has the promised capabilities.

Falsified Certifications and Non-Compliance

Some suppliers display fake CE, ISO or RoHS certificates and may use lower-quality raw materials to cut costs. You risk shipment blocks, financial losses, and even legal penalties if discovered during customs clearance or post-shipment inspections.

Overstated Production Capacity

Suppliers often exaggerate their production capacity to secure deals. Once committed, you may face delays, subcontracted production to unknown facilities, or even partial order cancellations.

Stop Taking Risks – Send an Auditor Onsite

Our audit teams conduct physical inspections directly at the supplier's factory — anywhere in Asia, Eastern Europe, North Africa, Turkey, and beyond. You get factual, unbiased verification before making any financial commitment.

On-site audits wherever your supplier are

No matter where your supplier is located, we dispatch our experts directly onsite. Asia, Europe, Africa — we go there for you. You get full visibility into the factory, equipment, workforce, and certifications before signing any contract.

A Thorough Audit

That Covers Everything

We follow a strict and comprehensive process that examines every key aspect of your supplier:

- Legal and Administrative: company status, licenses, registrations.

- Production Capacity & Quality: machinery condition, production workflow, internal quality controls.

- Compliance and Standards:CE, ISO, RoHS or other applicable industry certifications.

You know exactly who you’re dealing with.

Informed Decision Within 48 Hours

Once approved, we schedule the audit within 48 hours. The auditor completes the inspection onsite, and you receive a full illustrated report within 24 hours. In just a few days, you have everything you need to make a safe and informed decision.

Don’t leave anything to chance. Get full visibility into your supplier’s situation.

How Our Supplier Audit Works: 5 Simple Steps

We thoroughly vet suppliers to ensure reliability, quality, and compliance at every step.

Project Scoping

You share your needs, product type, volumes, and key concerns to investigate.

Audit Planning

We prepare a tailored audit checklist based on your sector and specifications, which we validate together.

Onsite Factory Audit

A DocShipper inspector visits the supplier’s factory to conduct the full onsite assessment.

Comprehensive Report Drafting

We compile a detailed report including photos and all verified legal documents.

Report Delivery Within 24 Hours

You receive the full audit report within 24 hours, giving you a clear basis for your supplier decision.

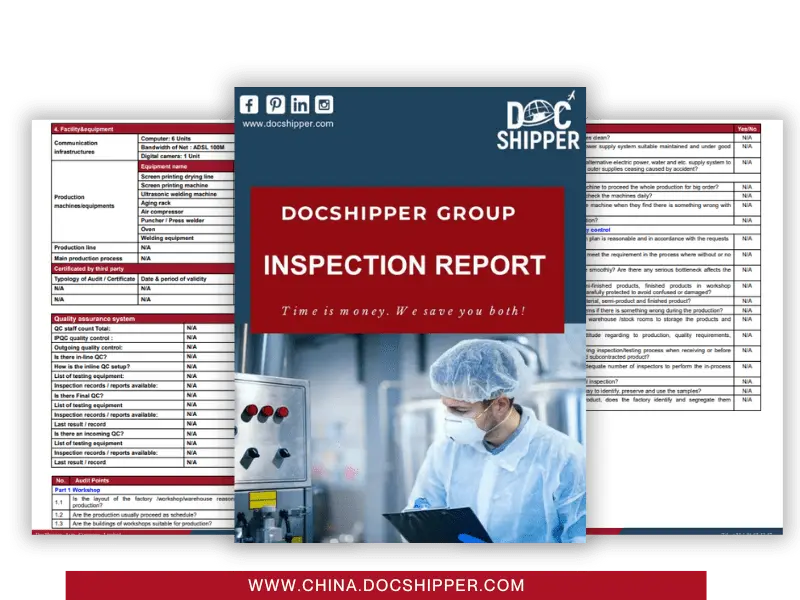

What’s Included in the Audit Report?

We verify the supplier's legal and corporate status:

- Company name, official address, incorporation date, legal structure.

- Licenses and certifications: commercial permits, customs licenses, import/export certificates.

- Regulatory compliance: authentication of submitted legal documents.

We assess what the supplier can truly produce:

- List of available machinery and equipment, condition, and maintenance status.

- Real daily and monthly production capacity.

- Raw material sourcing and inventory management.

We evaluate the factory's ability to operate efficiently:

- Staff count and roles (operators, technicians, management, quality teams).

- Department structures.

- Skills and qualifications of key personnel, especially the quality team.

Critical for ensuring compliant finished products:

- Quality certifications (ISO 9001, ISO 19011) verified onsite.

- Quality control procedures during and after production.

- Available testing equipment used for inspections.

We verify your products meet applicable regulations:

- Verification of CE, RoHS, ISO or other sector-specific standards.

- Product compliance with destination market requirements.

We thoroughly inspect production and storage environments:

- Storage conditions for raw materials and finished goods.

- Safety compliance (fire extinguishers, emergency exits, etc.).

- Cleanliness and organization of production and warehouse areas.

Each inspected point is scored to help you assess supplier reliability:

- Scoring system (100%) with visual indicators (green = compliant, yellow = needs improvement, red = non-compliant).

- Clear, actionable recommendations to help you validate or reject the supplier.

For maximum transparency:

- Photos of the factory, equipment, and production lines.

- Copies of verified legal documents and certifications.

- Photos of inspected products or samples.

Download an Audit Sample Report

Download a full sample audit report to see how we analyze and assess your suppliers.

Clients Testimonials

We can't make this up, read why businesses are trusting us with their international sourcing every day.

I own a small custom furniture startup. I recently needed to import some materials from China and worked with DocShipper for the first time. Honestly, they made the whole process way simpler than I expected. My contact was super helpful, always checking in and answering my questions. It was my first import, so I was worried things would go wrong, but they handled it all like pros. Highly recommend!

Thomas Brecht

January 9, 2025

My name is Ad Van Den Bosh. I am a Dutch business man cross-trading in the Far East. I reached Robert Houwayek to clear a 40HC of greenhouse equipment from Qingdao, and deliver it to Lan Krabue in no time. He suggested that I request a Form E, which I did from the supplier, and was able to enjoy a preferential tariff treatment. DocShipper, a way to help you save both time and money!

Ad van den Bosch

March 5, 2024

Starting a sound book publishing business wasn’t easy. I had no experience sourcing from China, but Daniel from DocShipper made it possible. He took care of everything, finding a factory, production, quality even negotiating better deals than I imagined!! He explained things clearly and eased my stress. Thanks to DocShipper, the whole process went smoothly. I’m excited to work with them again in the near future!

Grace O’Donnell

October 13, 2024

As a small fashion business owner, I was nervous importing my new collection from a new supplier. I didn’t know what to expect, bu they explained every step and answered all my questions without any condescension. The team was patient, knowledgeable, and efficient. The goods arrived on time and exactly like the sample. I’m so happy with how things went and will definitely rely on them for future imports.

Jasmine Nguyen

January 5, 2025

A vice president caught up in the thick of thin things, an EXW shipment of plumbing supplies for irrigation from Eureka California to Caldera Costa Rica is definitely not what I’d like to have on my agenda. [...]This time he skillfully handled all US export formalities incl. SED/AES filing, pre-pull drayage, not to mention the sea freight from Oakland POL by a 20-footer. Everything ended up working out like a charm!

Dave Sheppard

July 10, 2024

DocShipper shipped a 20- ft Milvan overseas to Laem Chabang for a customer. The team was responsible for shipping the shipping to another country. Having very little knowledge in this area, I didn't know how to organise myself . One week after my arrival on the Asian continent. Marc O. Was available at all times and nearly instant feedback. Made a stressful event much easier and he definitely knows his job.

Anonymous, Indiana

Aug 9, 2023