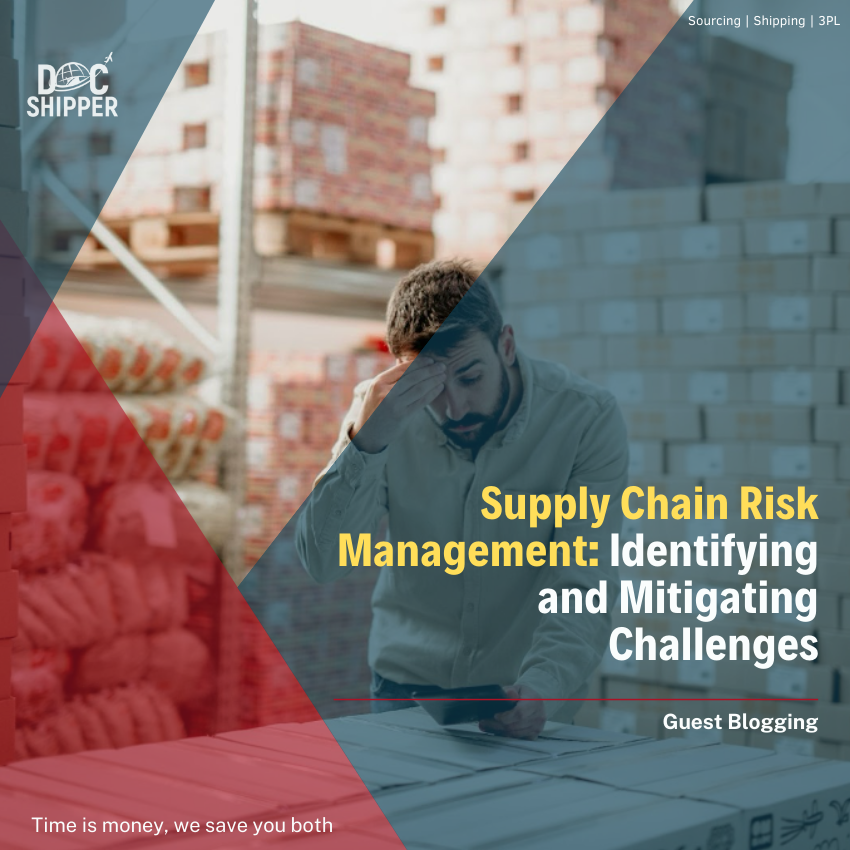

Since the coronavirus pandemic triggered widespread shortages and delays, the global supply chain has been playing catch up. Geopolitical issues, such as the Ukraine conflict and rising tensions in the South China Sea, have compounded these woes. Furthermore, incidents like the Suez Canal blockage have highlighted the importance of building up supply chain resilience.

As per a 2023 Supply Chain Outlook report, 60% of small and medium-sized businesses reported losses of up to 15% or more in 2022. In 2021, nearly half of all small businesses reported to the US Chamber of Commerce that they struggled to keep up with customer demand.In the face of increasing labor shortages, fluctuating demand, and inventory issues in 2024 and beyond, businesses must do more to maintain a more resilient supply chain.

It is vital to identify supply chain risks and challenges to develop effective measures to mitigate them.That is what you will discover in this article !

Understanding Supply Chain Risks

The supply chain is a complex network of processes and operations that ensure goods and services are delivered to the consumer. There are risks at every stage, and they encompass a broad spectrum of categories.

Operational Risks

Operational risks arise from an organization’s internal processes. Examples include equipment breakdowns, human error, production issues, or inventory mismanagement. There is also the threat of theft, fraud, or cyberattacks. These can lead to delays, increased costs, and quality issues that impact a company’s reputation and customer satisfaction.

Financial Risks

Businesses also face financial risks like currency exchange fluctuations, budget overflows, or constructive changes. Global issues like inflation can also be challenging. External factors, such as a third-party supplier filing for bankruptcy, are also considered financial risks. Financial risks for firms can also be exacerbated by fluctuations in interest rates and financial market volatility, which can have a big influence on borrowing costs and profit margins.

Logistics Risks

Transportation and logistics are the backbone of the supply chain, as ensuring the smooth passage of goods minimizes delays and ensures customer satisfaction. Logistics risks can arise from internal factors (mismanagement of warehouse space, inefficient route planning) or external ones (fluctuating fleet management costs or natural disasters affecting transport routes).

Compliance Risks

Globally functioning organizations are subject to international laws, norms, and industry standards, including labor laws and intricate environmental, social responsibility, and governance restrictions. Infractions of these regulations may lead to penalties, hefty fines, and even irreversible financial losses. Therefore, in order to prevent these unfavorable outcomes, businesses must implement strict monitoring and compliance procedures.

Environmental Risks

Storms, droughts, floods, hurricanes, and other extreme weather events are becoming more common, posing an immense threat to the global supply chain. Moreover, businesses that don’t follow environmentally friendly practices when sourcing and transporting goods risk alienating eco-conscious consumers.Businesses should invest in robust infrastructure, sustainable practices, and disaster preparedness strategies to reduce these risks.

DocShipper Tip

DocShipper Advice : DocShipper Sourcing is your ideal partner for sourcing in Asia. We manage everything from sourcing vetted suppliers to product customisation and quality control. Focus on your business, we’ll take care of the rest;Contact us!

Tools to Identify Supply Chain Risks

Organizations must conduct comprehensive risk assessments to identify supply chain issues. These methods and tools can help:

01. SWOT Analysis

-Strengths: An organization’s competitive advantage comes from internal elements. Strong supplier relationships, effective logistics, and the adoption of cutting-edge technology are examples of strengths for supply chains.

-Weaknesses : those are generally Internal issues that impair performance. Examples in supply chains could be an excessive dependence on one supplier, a lack of openness, or insufficient risk control.

-Opportunities are outside variables that can be taken advantage of. New technologies, regulatory changes, or industry trends may present opportunities.

-Threats: Outside dangers that might compromise the chain of supply. These could involve abrupt changes in demand, natural calamities, or geopolitical instability.

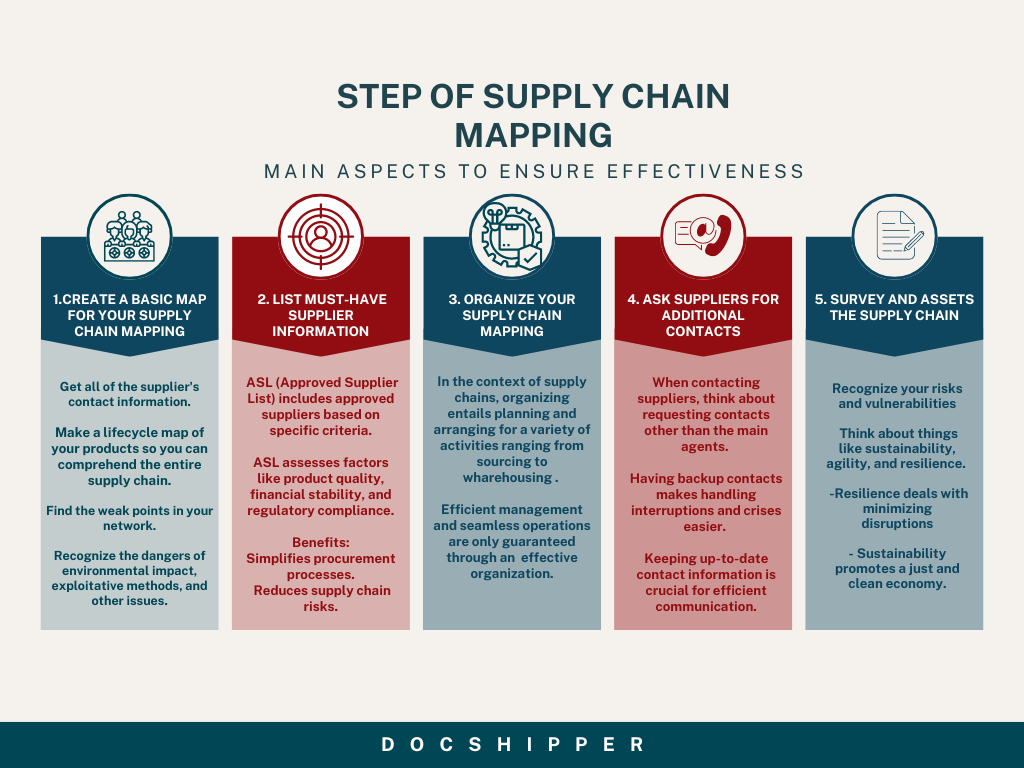

02. Supply Chain Mapping

Risk mapping is a strategic process that helps organizations identify weaknesses in the supply chain. It involves collecting key data about all suppliers and service partners to create a data map that details where materials are sourced from and how goods are moved. With a comprehensive map, organizations can identify bottlenecks that affect the movement of goods and environmental concerns that impact specific suppliers.

03. Key Risk Indicators

Key risk indicators are metrics that track risks like suppliers’ financials, geopolitical issues, or extreme weather events that can affect the flow of goods.

-They may be connected to monetary expenses.

-They can be measured carefully and accurately.

-They give out a lot of confidence.

-They gauge the factors connected to the choices made.

Evaluating and Prioritizing Risks

Next, evaluating and prioritizing supply chain risks based on likelihood and severity is essential.

Here are some approaches for businesses:

- Qualitative vs Quantitative Analysis:

To determine the possibility of hazards, qualitative risk analysis depends on expertise and experience.As an illustration the risk management team confers with specialists and evaluates the probability of strikes by using historical data and contextual elements.

On the other hand, the quantitative method depends on factual data to furnish details on the procedure. For example,the business gathers information on previous strikes, strike rates by area, late delivery expenses, etc. They compute a striking probability using this data and they make advantage of this information to determine a strike action probability that is more precise.

- Risk Matrix:

Businesses can visualize possible supply chain risks by using the risk matrix, which takes into consideration likelihood and potential impact. Example: The risks related to raw material supply are evaluated by the company. Because of the heavy reliance on a single source and the price fluctuation, they rate the probability of a raw material shortage as “high.” Conversely, there is a “low” chance that office supply may run out of stock.

- Failure Mode and Effects Analysis:

FMEA finds possible issues in a system, product, or process. Applied to supply chain risk management, it helps businesses find inefficient procedures, predict stock outages, adhere to legal requirements, and much more.

For instance They learn that a particular machine has a high failure risk, which could result in production delays. To reduce this risk, they implement a preventive maintenance strategy.

DocShipper Info

DocShipper info : Quality control is crucial because it aids in assessing the amount and caliber of items. DocShipper offers quality control services and helps you with all logistics procedures.Contact us at any time to obtain a free quote, and one of our specialists will get back to you within a day.

Mitigating Supply Chain Risks through different strategies

Here are some proven strategies to ensure resilience in the supply chain:

01. Diversification of Suppliers

In the face of widespread disruption, supply chain diversification has become more important than ever. Organizations can benefit from increased agility and flexibility, as well as minimize environmental, logistical, and financial risks. By diversifying their suppliers and production locations, companies can enhance their resilience and adaptability in an ever-changing global landscape.

An Earnst and Young survey from 2022 reported that 77% of businesses were planning to increase their total number of suppliers. Of these, 63% said they were looking to increase the number of countries where they have suppliers, and 55% said they were shifting their supplier footprint closer to their operations.

Both approaches have their benefits. Multi-shoring can reduce the risk of a local event, such as a flood or conflict, from affecting operations. Meanwhile, a supplier closer to home, or near-shoring, minimizes delays and significantly reduces costs. Balancing multi-shoring and near-shoring strategies allows companies to optimize risk management while maintaining operational efficiency

02. Inventory Management

Improving inventory management is one of the most effective ways to mitigate supply chain risks. Poor inventory management results in stock outs, lost sales, and increased storage costs.

With better inventory forecasting, businesses can predict future demand and ensure they always have the right amount of inventory to meet demand.

DocShipper Tip

DocShipper Advice : With its 11 years of experience in the E-Commerce industry, Docshipper offers specialized third-party logistics (3PL) services. They can manage your stocks and distribution, ensuring efficient inventory management and super-competitive shipping prices throughout Europe. Plus, you’ll have real-time access to your inventory and stock. Feel free to contact us to get a free quote!

03. Strategic Sourcing

Strategic sourcing is a comprehensive strategy that helps organizations choose suppliers with the least possible risk. It leverages long-term market analysis, goal recognition, and constant monitoring to help businesses find high-quality suppliers at the lowest possible cost. This reduces risk and increases overall profitability in the long run with like-minded suppliers.

04. Risk Sharing Contracts

A risk-sharing contract dictates that suppliers and businesses share risks associated with unexpected issues, encouraging both parties to do their part in minimizing delays. In the event of a disruption, this agreement outlines the responsibilities of both parties, simplifying the process of resolving issues. The contract can be worded to trigger in the case of delays, quality issues, or supply chain disruptions.

DocShipper Tip

DocShipper Advice : DocShipper can also ship your goods by sea freight (LCL or FCL), air freight, rail freight or even road freight. Let the experts guide you through every step of the freight forwarding process, take advantage of our door-to-door services and take the burden off your shoulders.Contact us now we will be glad to assit you!.

Building Resilience in the Supply Chain

Resilience refers to the ability of the supply chain to respond to potential disruptions. The concept has become crucial in the last few years as transport congestion issues, extreme weather events, and other supply chain problems have become more common. The advantages of applying resilience are:

- Establishing inventory and capacity buffers as a safety net.

- Diversifying suppliers to reduce dependence on a single partner.

- Standardizing processes, products, and facilities to maximize limited resources.

- Adopting cutting-edge technology to improve forecasting, streamline the flow of goods, and adopt more efficient practices.

- Developing strong relationships and strategic partnerships with suppliers and service providers to minimize the impact of disruptions.

Leveraging Technology for Risk Management

Streamlining an increasingly complex supply chain is no easy task. Fortunately, modern technology offers several solutions to improve operations and enhance risk management practices.

Predictive Analytics

Predictive analytics leverages historical data, statistical algorithms, and machine learning to anticipate demand fluctuations, improve inventory management, analyze supplier history, identify potential disruptions, or even predict the likelihood of a natural disaster.Furthermore, predictive analysis can study traffic patterns and road conditions to identify the best possible travel routes and minimize delays.

Predictive analytics leverages historical data, statistical algorithms, and machine learning to anticipate demand fluctuations, improve inventory management, analyze supplier history, identify potential disruptions, or even predict the likelihood of a natural disaster.Furthermore, predictive analysis can study traffic patterns and road conditions to identify the best possible travel routes and minimize delays.

Blockchain

Blockchain technology can vastly improve transparency, as it records all transactions on an immutable ledger that can be accessed by anyone on the supply chain. Apart from helping organizations ascertain potential risks, the technology can locate missing documentation, rectify payment mistakes, and prevent theft and fraud, thus reducing costs and minimizing delays.

IoT

IoT-enabled telematics has already proved its merit in streamlining logistics, helping organizations gather and analyze vast amounts of data from various touchpoints to identify and rectify potential supply chain bottlenecks.IoT digital twins are revolutionizing the manufacturing production process, allowing organizations to monitor devices, assets, and methods in real-time and use this information to reduce operational risks.

DocShipper Alert

DocShipper Alert : We comprehend that selecting and identifying a trustworthy supplier from the vast array of global suppliers and vendors can be a daunting task. This challenge is further exacerbated by the risks of fraud, communication barriers, and cultural differences, which can make the process even more complex and time-consuming. DocShipper provides sourcing and supplier quotation services; we can locate a trustworthy supplier capable of fulfilling your needs. Request a free quote right away.(Contact us!)

The Future of Supply Chain Risk Management

Organizations are increasingly grappling with the fragility of the supply chain and are making massive strides in improving resilience and mitigating risks. However,as rapid digitization brings more cybersecurity concerns and climate change continues to add unpredictability into the mix, new approaches and technologies must be constantly developed and applied to ensure we can build a sustainable supply chain.

Conclusion

Building a resilient supply chain requires continuous evaluation and adaptation. Companies must remain vigilant against emerging threats, such as cybersecurity risks associated with rapid digitization and the unpredictability of climate change. By leveraging innovative technologies and strategic partnerships, businesses can enhance their supply chain resilience, ensuring stability and sustainability for the future.

In conclusion, the road ahead for supply chain management is fraught with challenges, but it also offers opportunities for innovation and growth. By proactively addressing risks and embracing technological advancements, organizations can not only weather current disruptions but also build a robust foundation for future success in the ever-evolving landscape of global trade.

FAQ | Supply Chain Risk Management: Identifying risks and Challenges

Read more

Looking for more? These articles might interest you:

DocShipper info: Do you like our article today? For your business interest, you may like the following useful articles :

Need Help with Logistics or Sourcing ?

First, we secure the right products from the right suppliers at the right price by managing the sourcing process from start to finish. Then, we simplify your shipping experience - from pickup to final delivery - ensuring any product, anywhere, is delivered at highly competitive prices.

Fill the Form

Prefer email? Send us your inquiry, and we’ll get back to you as soon as possible.

Contact us