If you are planning on launching a new product or making improvements on an existing one but you don’t have enough expertise, budget, or time to manufacture all the needed components, you might consider using an OEM or ODM service.

In the manufacturing industry, OEM and ODM are two distinct processes. OEM involves designing and producing a product for another company’s brand, while ODM consists in designing and manufacturing a product for another company’s brand. This article will explore the differences between OEM and ODM and their respective advantages and considerations for companies choosing between the two.

What is OEM?

OEM stands for Original Equipment Manufacturing, by definition, it is the process of designing and producing a product that is sold by another company under its own brand name.

Meaning that, if use this service, and you are a telecom company, you will use another smartphone company to make the phone for you and you will sell this phone under your own brand as if it is your own product.

Advantages of OEM

Here is what using an OEM service can offer you :

- Cost savings: Since the manufacturer can produce products in large quantities, it can achieve economies of scale, resulting in lower production costs.

- Focus on core competencies: By outsourcing manufacturing to an OEM, companies can focus on their core competencies such as branding, marketing, and distribution.

- Reduced risk: Outsourcing manufacturing to an OEM reduces the risk of investing in new products and technologies, as the OEM has the necessary expertise and resources.

Disadvantages of OEM

Using this service also comes with a downside that you must be aware of such as :

- Limited control over the final product: Since the OEM manufactures the product based on the buyer’s specifications, the buyer has greater control over the final product, leaving the OEM with a limited say in the design and manufacturing process.

- Reduced profit margins: The manufacturer receives only a portion of the profits earned from the sale of the product, which can lead to reduced profit margins.

- Dependence on the buyer: OEM manufacturers are dependent on their buyers for orders and revenue, which can make them vulnerable to changes in the market and the buyer’s demands.

What is ODM?

ODM stands for Original Design Manufacturing. It refers to the process of a company designing and manufacturing a product for another company, which is then sold under the buyer’s brand name.

Meaning that, if you are à clothing company, you may use another company to design and produce clothes for you based on your own specifications and then sell them under your brand name.

Advantages of ODM

Here is what using an ODM service has to offer :

- Customization: The buyer has greater control over the design and manufacturing process, which allows for more customization and the ability to create products that meet their specific needs.

- Reduced risk: Outsourcing product development and manufacturing to an ODM manufacturer reduce the risk of investing in new products and technologies, as the ODM manufacturer has the necessary expertise and resources.

- Brand recognition: Since the product is sold under the buyer’s brand name, there is greater potential for brand recognition and customer loyalty.

Disadvantages of ODM

Here is what you must be aware of before opting to use this service :

- Higher costs: The buyer may have to pay a higher price for the product due to the added costs of design and development.

- Limited control over the manufacturing process: While the buyer has greater control over the design process, they may have limited control over the manufacturing process, which can result in a product that does not meet their quality or functionality requirements.

- Dependence on the ODM manufacturer: ODM manufacturers are responsible for the design and manufacturing process, which can make the buyer dependent on their capabilities and expertise. If the ODM manufacturer experiences issues or delays, it can impact the buyer’s ability to deliver products to the market on time.

DocShipper Alert

Maximize Your Manufacturing Efficiency with Docshipper! Our Procurement Experts Will Guide You Through the OEM/ODM Selection Process and Help You Achieve Cost Savings. Get in Touch Today.

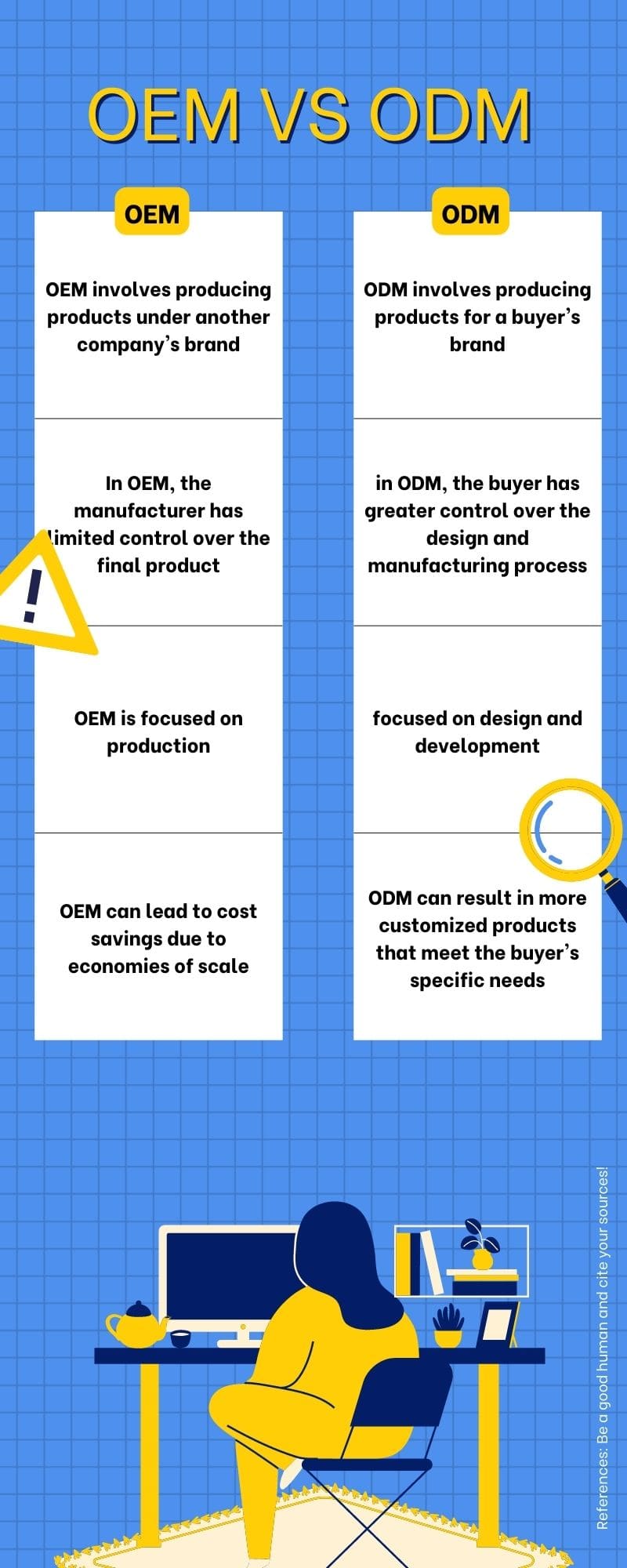

Difference between OEM and ODM

It can be hard and a bit confusing to comprehend the exact difference between the two services for beginners, below you’ll find the distinction between services in the simplest way possible :

- OEM involves producing products under another company’s brand, while ODM involves producing products for a buyer’s brand.

- In OEM, the manufacturer has limited control over the final product, while in ODM, the buyer has greater control over the design and manufacturing process.

- OEM is focused on production, while ODM is focused on design and development.

- OEM is ideal for companies that want to expand their product offerings, while ODM is ideal for companies that want to sell products under their own brand name.

- OEM can lead to cost savings due to economies of scale, while ODM can result in more customized products that meet the buyer’s specific needs.

- In OEM, the manufacturer receives only a portion of the profits, while in ODM, the buyer bears the cost of design and development, resulting in higher prices.

Who are the biggest OEM and ODM providers?

If you are contemplating about getting into this game then you must look up its major players, which will help you choose the right service provider.

- Foxconn – is a Taiwan-based company that specializes in electronic manufacturing services and is the world’s largest OEM company.

- Quanta Computer – is also a Taiwan-based company that is a leading provider of ODM services in the computing industry.

- Flex – is a Singapore-based company that offers design, engineering, and manufacturing services to a variety of industries, including automotive, healthcare, and telecommunications.

- Pegatron – is a Taiwan-based company that provides ODM services for a wide range of electronics products, including laptops, smartphones, and game consoles.

- Wistron – is another Taiwan-based company that specializes in manufacturing and designing services for consumer electronics, such as smartphones, tablets, and computers.

- Jabil – is a US-based company that provides design, engineering, and manufacturing services to various industries, including healthcare, automotive, and aerospace.

- Sanmina – a US-based company that offers a wide range of manufacturing services, including design, engineering, and supply chain management, to customers in various industries.

Who are the biggest OEM and ODM users?

Here are a few examples of big companies using the OEM and ODM services that we recommend you study them in order to better understand this business :

- Apple – The iPhone and MacBook are manufactured by Foxconn and Quanta Computer respectively, both of which are major ODM/OEM providers.

- Samsung – The Korean tech giant uses ODM services from companies like Wistron and Foxconn to manufacture its smartphones and tablets.

- HP – The computer and printer manufacturer uses ODM services from companies like Quanta Computer and Inventec to produce their products.

- Dell – Dell outsources some of its manufacturing to ODM providers like Foxconn and Quanta Computer.

- Microsoft – The software company uses ODM services from companies like Pegatron and Flex to manufacture its Surface line of tablets and laptops.

Should I choose OEM or ODM?

The decision to choose between Original Equipment Manufacturing or Original Design Manufacturing depends on your specific business needs and goals.

When deciding, considering the following is a must :

- With OEM, you work with a manufacturer to produce a product that already exists, but with your branding. The manufacturer produces the product to your specifications and you sell it under your brand name. This can be a good option if you want to focus on marketing and sales, and don’t have the resources to design and produce your own product.

- With ODM, you work with a manufacturer to design and produce a product according to your specific requirements. The manufacturer handles the entire process, from design to production, and you sell the product under your brand name. This can be a good option if you have a unique idea for a product but lack the expertise or resources to design and produce it yourself.

It’s also important to research and vet potential manufacturers to ensure they have the experience and expertise to meet your needs.

What to consider when choosing an OEM/ODM service provider?

here are the steps to follow when choosing an OEM/ODM service provider for your manufacturing needs:

- Consider experience and expertise: Look for a company with a proven track record in manufacturing products similar to yours and has expertise in your industry and the type of product you want to manufacture.

- Evaluate quality control: Make sure that the OEM/ODM service provider you choose has a robust quality control process and is committed to producing high-quality products.

- Check communication and collaboration skills: Effective communication and collaboration are critical when working with an OEM/ODM service provider. Check if they have good communication skills and are willing to work closely with you throughout the manufacturing process.

- Evaluate production capacity: Consider the production capacity of the OEM/ODM service provider and ensure that it aligns with your manufacturing needs.

- Compare pricing: Compare the pricing of different OEM/ODM service providers and choose the one that offers the best value for your money.

- Check delivery time: Ensure that the OEM/ODM service provider can deliver your products within your required timeframe.

- Consider intellectual property protection: Ensure that the OEM/ODM service provider has adequate measures in place to protect your intellectual property.

- Check certifications and compliance: Ensure that the OEM/ODM service provider has the necessary certifications and compliance requirements.

- Evaluate customer service: Check the customer service of the OEM/ODM service provider and ensure that they are responsive and willing to address any concerns you may have.

By following these steps, you can choose the right OEM/ODM service provider that meets your manufacturing needs and provides you with the best value for your money.

Steps to follow if decided to use an OEM/ODM services in china :

Now that you have made up your mind about using this service, the first thing that you must do is Defining your product requirements meaning that you have to Clearly define your product design, specifications, quality standards, materials, and production volume and after that you must choose à service provider.

TIP : Most people use OEM/ODM services in China because it offers lower production costs, access to technology and expertise, efficiency, customization, and scalability. With a large manufacturing industry, Chinese OEMs/ODMs can produce products quickly and efficiently, often in large quantities. Additionally, customization services allow companies to tailor their products to meet specific customer needs, and scalability means that production can easily be increased to meet growing demand and that is exactly why we recommend that you start there and do your own research.

Here is a list of the biggest OEM/ODM service providers in china :

- Foxconn Technology Group

- Quanta Computer Inc.

- Wistron Corporation

- Compal Electronics Inc.

- Pegatron Corporation

- BYD Company Limited

- Inventec Corporation

- Flex Ltd.

- Jabil Inc.

- Celestica

Once you identify potential partners, evaluate their capabilities by reviewing their portfolio, production facilities, quality control systems, and certifications. To ensure that the partnership is satisfactory for both parties, negotiate the terms of the agreement including pricing, lead times, minimum order quantities, payment terms, and other details. after you agree upon terms, finalize the partnership by signing a contract that outlines the agreement’s terms and conditions, including quality control measures, intellectual property rights, and dispute resolution procedures.

Now that you did all the hard work, all that is rest for you do as à client is the following :

- Manage the production process: Maintain communication with your OEM/ODM service provider throughout the production process. Conduct regular inspections to ensure that the product meets your specifications and quality standards.

- Arrange shipping and delivery: Once production is complete, arrange for shipping and delivery of the products. Make sure that all necessary documentation, such as customs clearance and certificates of origin, are in order.

- Follow up: After the products are delivered, follow up with your OEM/ODM service provider to ensure that everything went smoothly and to address any issues that may arise. This will help establish a long-term relationship with your service provider and ensure that future orders are handled efficiently.

FAQ | Choosing Between OEM and ODM: A Decision-Maker’s Guide

Read more

Looking for more? These articles might interest you:

Info DocShipper : Do you like our article today? For your business interest, you may like the following useful articles :

Need Help with Logistics or Sourcing ?

First, we secure the right products from the right suppliers at the right price by managing the sourcing process from start to finish. Then, we simplify your shipping experience - from pickup to final delivery - ensuring any product, anywhere, is delivered at highly competitive prices.

Fill the Form

Prefer email? Send us your inquiry, and we’ll get back to you as soon as possible.

Contact us