What is a supplier? A supplier is a corporation or individual who provides various required resources to the business and its competitors, including the provision of raw materials, equipment, energy, and labor.

Normally, the condition of a supplier has a huge impact on the marketing activities of the enterprise. For instance, raw material price changes or shortages will affect the product’s price and delivery time, which will, therefore, weaken the long-term cooperation and profits of enterprises and customers.

As a consequence, marketers must have a more comprehensive understanding and thorough analysis of the supplier’s situation. The supplier is both a competitor as well as a partner in business negotiations.

So, how we choose the best supplier for our business? Follow us if you want to know more details! Want to learn more about our services, fill our online form: Contact Us.

The best supplier lays a solid foundation for the supply chain

What is a supply chain

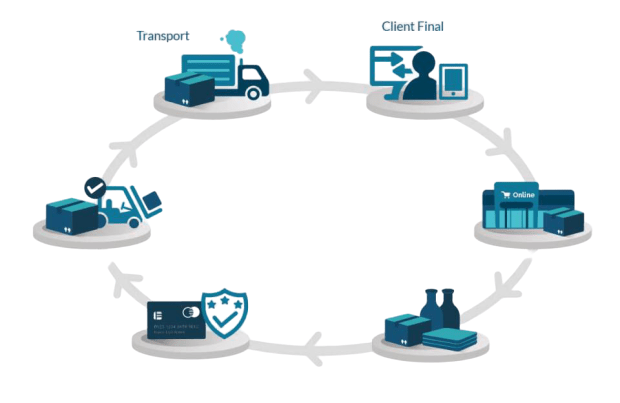

Supply chain refers to the network structure formed by upstream and downstream companies that provide the products or services to the consumers involved in the production and distribution process.

Instead of all those complicated definitions, we can describe the supply chain as a lush tree: the manufacturing company constitutes the root; exclusive agents are the trunk; distributors are the branches and treetops; the leaves and flowers are the end-user. All these fragments make the supply chain a complete process. Now recall that we have a role model company in supply chain management- Zara, try to understand the whole relationship and each fragment under this prestigious company. Find Zara’s supply chain.

To put it in another way, in the supply chain “enterprise A, enterprise B, and enterprise C“, enterprise A is the raw material supplier of enterprise B, enterprise C is the seller of enterprise B’s products. If enterprise B ignores the interdependence of all elements of the supply chain and focuses too much on its own internal development, the ability to produce products continues to improve, but if enterprise A can not provide him with raw materials in a prompt manner, or the sales capacity of enterprise C can not keep up with the development of enterprise B’s production capacity, then we can conclude that the development of enterprise B’s productivity is not adapted to the overall efficiency of the supply chain since it ignores the integration of supply chain.

How does the supplier influence the supply chain

The right supplier is the most essential part to enable the whole supply chain to function smoothly. Since for both enterprise and customer, the supplier works as the intermediary which connects them in an evident way, the correct selection of suppliers has an increasing influence on the supply chain operations and become the key to achieve a win-win situation in the supply chain. Under that condition, it is important to choose the best suppliers to enhance the overall competitiveness of the supply chain. As enterprises increasingly focus on the training of core competencies and core business development, it is inevitable to obtain resources from external sources.

In addition, changes in the globalization of commerce environment make the scope of supplier selection is no longer limited to a certain region but based on the network of global supplier selection. The application of various advanced manufacturing models requires rapid and efficient integration of manufacturing resources, which makes the selection of suppliers more complex and appears particularly prominent and important. For example, for the U.S., raw material procurement costs are typically about 40% to 60% of unit costs, external component costs for large automotive manufacturers account for more than 50 % of sales, and 30% of quality problems, as well as 80% of product deliveries, are caused by suppliers. Since US companies outsource some of the processes in various countries, there are some risks to take under the bright side of globalization.

Lastly, from a system perspective, manufacturing resources is the input of the entire manufacturing system, and the supplier’s behavior and factor market norms and manufacturing resources are closely related to the quality of any products, as a result, the selection of supplier is not only the basic point of manufacturing but also the success or failure of the whole supply chain!

A competent supplier is the trump card of the enterprise performance

A competent supplier is one that has the processing technology of manufacturing high-quality products, sufficient production capacity, and the ability to offer competitive products while making a profit. Fast, continuous, and unpredictable competitive environment requires the best quality and service in the shortest possible time to influence the market demand quickly. That is, the choice of the supplier has a direct impact on the profitability of the business, provided certain requirements are met.

DocShipper Tip

DocShipper Advice : You should always keep in mind that DocShipper will always work on optimizing the logistic processes in order to maximize your results, your costs and will also support you throughout the purchasing process: supplier research, negotiation, quality control.

Guidelines to follow during the selection of suppliers

The establishment of a good relationship is conducive to the reduction of costs, response time, and the creation of new market value. As we know that the core issue of those problems is how to select the ideal supplier since supplier evaluation problems involve many factors. Despite the fact that the evaluation system is diverse, here are some basic principles for people to following.

Completeness and simplicity

Provided that supplier information is sufficient, the number of indicators selected should be as few and concise as possible, and there should be no strong correlation between the indicators and no overlapping of indicators due to excessive inclusion and coverage of the information.

Objectivity and comparability

The selection process should not be affected by subjective factors as far as possible, according to the survey, qualitative indicators are more tend to be subjective factors, which can easily engender understanding bias, while quantitative indicators are easy to quantify and measure, so quantitative indicators should be selected as far as possible.

Configurability and extensibility

The evaluation indicator system should not only have quantitative changes, but also content changes, and users can modify, add and delete indicators according to different requirements, and further specify the evaluation indicators according to the specific situation.

Risk minimization

Supply chain operations are risky, and risk issues must be carefully considered to avoid or reduce the overall supply chain operational risk as much as possible.

Preparations required for choosing the supplier

Source of the supplier

When it comes to the source of the supplier, there are plenty of options. We can be familiar with a supplier in a products catalog, and maybe in the advertisements of trade journals, or in some professional website. Meanwhile, some supplier will send out representatives to visit for the cooperation, even people working in the same industry will give us some introductions of the best-quality suppliers.

Qualifications of the supplier

Remember to check the qualifications before work with one supplier. Needless to say, the first and foremost one is a manufacturing license. The product inspection report should be examined as well, when collaborating with a supplier, we should make sure that the products he manufactures are legit. Last but not least, not only the supplier’s status and influence in the industry but also the reputation should be inquired into.

DocShipper Alert

DocShipper Advise: You don’t have to worry about your logistical routing and the conformity of your electrical products, you can count on our 3PL (Third Party Logistics) to handle the entire process safely. Do not hesitate to contact our agents!

Getting an assessment of the products

Now that we have already known all the principles as well as the preparations and the importance to choose a competent supplier, here comes the product part. We have to make sure every cycle of products will be perfect and no accidents will happen.

Products procurement cycle

The right product plays a very important role in a company. Some companies have specific standards while others have no reference to check. In this way, the company should take care of every procurement cycle and specify various products’ colors or weight, in case of accidents happen. Identifiers like quality, quantity, and specific requirements of the products should be checked meticulously.

Intention price of the products

Price is of great importance among all the processes, so what are the ways to procure the products with the best price? The followings are various ways to quote.

Uncommitted offer

Such quotes are generally used as a reference, the seller quotes according to the market price of the specific day. However, if there are price fluctuations, the seller will adjust its price. As a consequence, be sure to declare: “the offer is not bound by the commitment“, or “the offered price increases or decreases based on the market price “or “the price is subject to change at any time without notice“.

Quotation confirmed by the seller

This kind of offer must be confirmed by the seller before it becomes effective, this kind of offer is better than the uncommitted offer, it expresses the buyer’s sincerity about this business, and at the same time prevent risk. However, if there are special conditions, the seller can explain the reasons for the cancellation of the confirmation.

The offer that can be sold first

This offer is beneficial to the seller, the seller offers a batch of goods at the same time to two or more customers. If someone accepts the quotation first, for the later acceptance of the offer, the price of the goods which have been already sold out automatically invalidation.

Quotation agreed by the buyer

This also known as the offer has permission to return the goods, that is, the buyer must see the goods and be satisfied before the establishment of the offer, this kind of offer is extremely unfavorable to the seller, therefore is rarely used by people.

DocShipper Info

DocShipper Advise: You can count on DocShipper if you’re in need of any packaging and protection service to relive. Do not hesitate to contact us.

Ways to reduce procurement costs

Reduce procurement costs through the choice of payment terms

If the capital of the enterprise is abundant, or bank interests are low, cash transactions can be used in a way that is more efficient and effective. But if it’s not in this case, compare each way with professional suggestions. Remember to obey the rules that it should minimize the occupation of working capital and demand whichever you choose, which is conducive to expanding the scale of production.

Grasp the best timing of price changes

Prices will often change along with the seasons as a result of the variations of market supply and demand, therefore, procurement should pay attention to the law of price changes and grasp the timing of procurement. If the procurement department can grasp the timing and the number of purchases, it will bring great economic benefits to the enterprise.

Win an advantageous place through competitive bidding

For bulk material purchases, an effective method is to implement competitive bidding, which often results in the acquirement of a bottom-line price by comparing suppliers’ prices with each other. In addition, for the same material, companies should find several suppliers, through the selection and comparison of different suppliers so that the company is in a favorable position in the negotiations.

Understand the cost of suppliers

To achieve full control of procurement costs, internal efforts are not enough. Understanding the reasonable cost of supply-side when the purchaser in negotiations with suppliers of the level is an effective weapon. In this way can the purchaser take the initiative in the negotiations. After the estimation of supplier costs and understand what materials account for a larger proportion of the cost, the purchaser can press the supplier’s profit margin at a lower level. In order to establish long-term relationships with suppliers, the purchasers can work together with suppliers in a way that reduces the cost of bulk materials, towards the goal of higher quality and lower costs.

Assistance from professional freight forwarder: Docshipper

When people decide to choose a supplier, there are plenty of rules to follow. They should be familiar with all the information as much as possible, at the same time improve their own competence, not to mention the qualifications of the suppliers and products need to be inspected. Furthermore, when dealing with various suppliers from different countries who share totally different languages and cultures with you, the difficulties can drive you crazy sometimes. The best suggestion for you is to find a professional agent: Docshipper. Once you’ve found your positioned suppliers, there still will be a lot of things to manage if you want to import them from overseas markets. We’ve built our business model to assist our clients in the whole product cycle and our goal is ” Focus on your marketing/sales, let us handle the rest!“

FAQs How to find the best supplier?

Read more

Looking for more? These articles might interest you:

DocShipper info: Do you like our article today? For your business interest, you may like the following useful articles :

- Coronavirus (Covid-19) impacts on import/export business

- How does Coronavirus impact international supply chain?

- 💡How to find a good product to sell?

- How to find your reliable supplier for your business? [Fair Trade Guide]

- AliExpress | Use the Chinese panacea to sell your products online

- How a sourcing strategy can rocket your margin?

Need Help with Logistics or Sourcing ?

First, we secure the right products from the right suppliers at the right price by managing the sourcing process from start to finish. Then, we simplify your shipping experience - from pickup to final delivery - ensuring any product, anywhere, is delivered at highly competitive prices.

Fill the Form

Prefer email? Send us your inquiry, and we’ll get back to you as soon as possible.

Contact us