The epidemic is still raging around the world, and though there is a sign of an easing of momentum, however, within some countries, they are still suffering from the disease. Along with the coronavirus, the ability of global economic recovery is weak, and a large amount of uncertainty makes it difficult for the manufacturing sector to recover.

Against the backdrop of economic globalization, the international supply chain relies on raw materials imported from overseas.

What exactly is a supply chain? How does Coronavirus impact the international supply chain? How can supply chain managers ensure the continuity of their operations in the face of global blockades and reduced international logistics capacity? Follow us if you want to know more information.

What is a supply chain?

Supply chain refers to the network structure during the production and distribution of products involved in the process of raw materials suppliers, manufacturers, distributors, retailers, and final consumers and other members through the upstream and downstream members of the connection (linkage). It is a network of companies and business units involved in the process of acquiring materials, processing them, and delivering the finished product to the customer.

What are the characteristics of the supply chain?

The structural model of a supply chain shows that a supply chain is a network chain structure with a demand and supply relationship between firms and firms. A supply chain has the following main characteristics.

Complexity. Because supply chain nodes are composed of different spans (levels) of enterprises, and supply chains are often composed of multiple, multiple types or even multinational enterprises, the structural model of the supply chain is more complex than that of a single enterprise in general.

Dynamics. Supply chain management is distinctly dynamic due to the need for corporate strategy and adaptation to changes in market demand, in which nodal firms need to be dynamically updated.

Responsiveness. The formation, existence, and restructuring of supply chains occur based on certain market demands, and the pull of user demand is the driving source of information flow, product/service flow, and capital flow operations in the supply chain.

Intersecting. A nodal firm can be a nodal firm in this supply chain and at the same time, a nodal firm in another supply chain, and the many supply chains form a cross structure, making it more difficult to coordinate management.

What is the process of a supply chain?

The supply chain generally includes four processes: logistics, commercial flow, information flow, and capital flow. The four processes have their own different functions as well as the different circulation direction.

Logistics

This process is mainly referring to the flow of materials (goods), which is a procedure for sending goods. The process is directed from the supplier to the consumer via the manufacturer, wholesale and logistics, retailer, etc. Because business theory has long been focused on the physical product, the material process is now widely valued. Many logistics theories are concerned with how to send out goods in a short period of time and at low cost in the process of material circulation.

Commercial flow

This process is primarily the flow of buying and selling, which is the business process of receiving orders, signing contracts, etc. The direction of this process is a two-way flow between suppliers and consumers. At present, the form of commercial circulation tends to be diversified: the traditional shop sales, door-to-door sales, mail order, and through the Internet and other emerging media for shopping e-commerce forms.

Information flow

This flow is the flow of goods and transaction information. It is also oriented towards the two-way flow between suppliers and consumers. The flow of information has been neglected in the past because of the tendency to focus on physical objects that are visible. Some people even think that the country’s logistics backwardness and their capital into excessive material processes and delays in grasping the information are not unrelated.

Capital flow

This process is the circulation of money, in order to ensure the normal operation of the business, it is necessary to ensure the timely recovery of funds, otherwise, the company can not establish a sound business system. The process is directed from consumers to suppliers via retailers, wholesalers, and logistics, manufacturers, etc.

what is the main activity of the supply chain?

According to the concept of the supply chain, it covers every business activity related to the formation and delivery of the final product or service from the supplier of raw materials, through the factory development, processing, production, wholesale, retail and finally to the user. Therefore the supply chain also covers the three main theories such as production theory, logistics theory, and marketing theory. The main activities of the supply chain include.

Development and manufacture of goods:

◊ Planning, design, commercialization of commodities.

◊ Demand forecasting and production planning.

◊ Commodity production and quality management.

Commodity distribution:

◊ Ensuring the stability and effectiveness of the distribution route, i.e. the distribution channel.

◊ On-time delivery, distribution management, and operations with a JIT mindset.

◊ Reduce logistics costs to achieve the lowest overall cost of the supply chain.

DocShipper Tip

Docshipper Tip : Air freight, although expensive, can reduce lead times. With disruptions throughout the maritime market, other competitors have also been able to reduce lead times. If you look at it this way, air freight costs are not just an expense on the books, but a means to help the company gain a competitive advantage. Docshipper provides you with the best service when it comes to shipping, no matter sea freight or air freight.

Marketing and after-sales service:

◊ Sales, with appropriate marketing mix strategies to achieve optimal sales.

◊ Complete and timely replenishment of commodities and maintenance of minimum stock levels.

Management of sales data and sales, understanding of problems, and defining guidelines for activities.

What’s the connection between Coronavirus and bullwhip effect

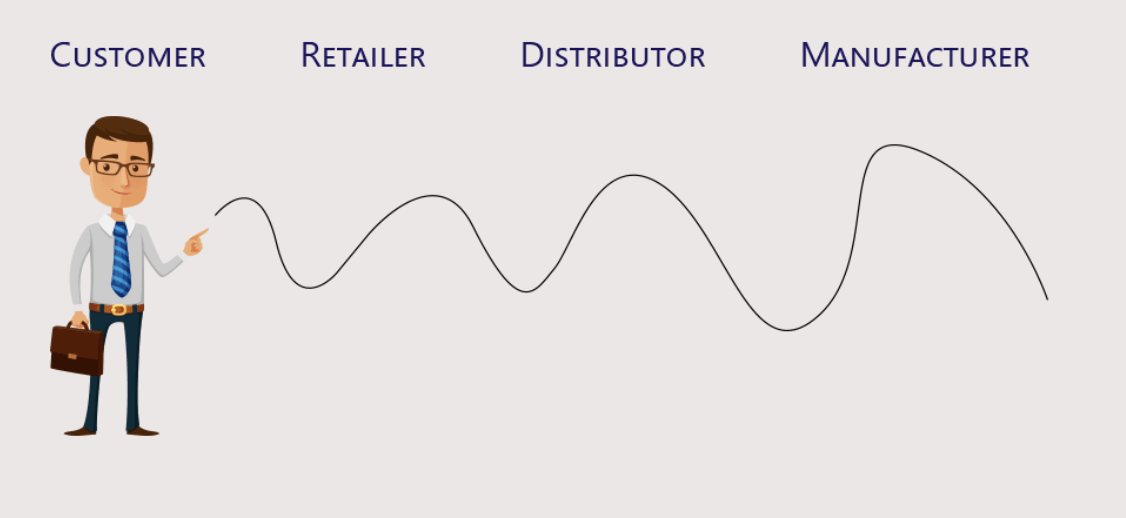

The bullwhip effect is a visual description of the transmission of demand information distortions in the supply chain. The basic idea is that at each node in the supply chain, when a firm makes production or supply decisions based only on-demand information from its subordinate firms, the untruthfulness of the demand information can backfire along the supply chain, producing a cascading amplification. By the time the information reaches the most source suppliers, the demand information they receive deviates greatly from the actual customer demand information in the consumer market. As a result of this demand amplification effect, the supply side tends to maintain higher inventory levels or production readiness plans than the demand side. Learn more about the correlation between Coronavirus and Bullwhip effect.

The recent outbreak of COVID-19 has caused a surge in demand for paper towels and personal disinfection products in many countries and regions around the world, which is a good illustration of the bullwhip effect. This demand is predicted to continue over the next year. The biggest obstacle to supply chain coordination in this process is the sharing of new information and the allocation of resources. The current epidemic is spreading around the world, and due to inconsistencies in production capacity and technology levels in different regions, as well as differences in demand levels, it is difficult to rationalize the specific distribution of these two types of products. Local monopolies or stockpiles will form in some places, while in others there will be large gaps. The sharing of information is difficult to achieve mutual understanding and comprehensive integration. Therefore, at the level of supply chain coordination, there is a serious imbalance between demand and supply in different areas, and in general, there is a phenomenon of demand exceeding supply. Both types of products are consumed in large quantities, and in order to better meet the changing needs of the future, cooperative mechanisms should be established across a large area to maximize the rational allocation of resources to where they are needed.

DocShipper Alert

DocShipper Alert : Although the covid-19 caused a huge damage in the international supply chain, we can still see the application of the bullwhip effect on the newly boomed products – paper and disinfect products. Since the whole supply chain is vulnerable than it used to, every process should be taken consideration into deeply, and we, as a professional agency, can provide all the stable services you needed.

Major new changes in the supply chain nowadays

The coronavirus outbreak has sent shockwaves through the delicate ecosystem of complex global supply chains. With this worldwide background, many companies are finding it impossible to quickly identify and connect with alternative suppliers, which is having a significant impact on production. And this impact may further affect the layout of the global chain. The duration of the epidemic will be so long that supply chains in the worst affected areas will face rupture or even disappear. Multinational companies’ supply chains also face post-disruption reconfiguration. PWC suggested that if the epidemic continues to spread through the end of the year even next year, some international producers will have to restructure their chains. As a result, in the process of restructuring the industrial chain in the future, the global supply chain will also show some new changes.

A shift from a cost orientation to a cost and risk orientation

Companies will no longer consider cost as the only factor when establishing supply chains but will establish a whole set of risk mitigation strategies. For companies, their main product must have multiple ways of reaching the marketplace instead of a single way as it used to applied. Today’s sophisticated supply chain networks allow people to remove the excess inventory and avoid idle capacity, it also takes away market demand elasticity, leaving no room for any disruptive events. The world is interdependent nowadays, but at the beginning of an outbreak of an epidemic, many people still believe that this is a problem of individual countries and that accordingly epidemic control of the enterprises or risk mitigation programs has not been developed in advance thus causing the abruption of the supply chain.

A shift from a global to a regionalized production

Regional production will lead to the formation of numerous supply chain centers. Global production chains will move towards smaller, more regionalized supply chains, and concentrating key production processes in a few key sites. In this way, the

Improvement of the transparency regarding the supply chain and identification of where the parts you need come from can better serve your needs thus dealing with risks successfully. For example, during the epidemic, Toyota maintained a good response to the risk of capabilities. This restructuring will have a structural impact on the global division of production networks, and we will see the development of it in the future.

Digitalization of global supply chains will accelerate

The digitization of global supply chains will be accelerating. Both in the short and long term, a priority for businesses is to better understand the vulnerabilities in their production processes. In addition, the company needs to locate all of its direct and indirect suppliers in detail which might lead to the accelerating of the digitization of global supply chains. Information flows and data values have multiple roles, and often used not only to support inter-enterprise production relations, planning, and coordination but also to accelerate a more nuanced understanding of production processes and customer behavior patterns. Digitalization allows multinational companies by adding or subtracting network units, adjusting multilateral platforms, or modifying existing links and interaction to rapidly change their business model and reduce supply chain management and transaction costs. Therefore, a digitally supported transnational platform will promote different sectors around the world in new ways.

What are the major influences of the supply chain due to Covid-19?

Overall, the impact of the epidemic on the supply chain can be seen in the following aspects:

(1) the global epidemic has led to a reduction in demand and supply and uncertainty in some of the industrial value chain, for example, China’s trade with Europe and the United States has been largely disrupted, resulting in the cancellation of a large number of orders from export-dependent enterprises;

(2) upstream factories shut down or reduce production, leading to downstream supply and production challenges, the manufacturing industry is more severely affected by the epidemic compared with other industries, such as supplier shutdowns and shortages of incoming raw materials or parts supply, which can impact manufacturing production and sales;

(3) some of the city blockades cause regional and international logistics terminals and delays, resulting in pieces of out-of-stock or backlogs. At the same time, it also leads to a default on contracts due to the inability to perform on time, which ultimately affects companies’ investment decisions being delayed or put on hold.

DocShipper Tip

DocShipper Advice : In this stage, the world is starting to reopen again, thus if you want to do business overseas, especially you are an export-import company, in order to guarantee a stable supply chain for yourself specifically with those enterprises in Asian, we have our own branch located in Asian and can offer great assistance! Don’t hesitate to contact us.

How to adjust the supply chain strategies?

The supply chain of the enterprise affects the whole process, the ability to face the rapid recovery of the delivery, inevitably involves market research and consumer guidance, product planning, category management, sales guidance, forecasting, planning and coordination, supplier capacity coordination, inventory use, the whole value chain information synthesis, and other aspects. It can be said that the better the supply chain foundation of the company, the more mature conditions for rework, short rework cycle, the stronger the delivery capacity; on the other hand, the supply chain foundation is relatively weak or lack of upstream and downstream collaboration of the enterprise, facing all kinds of factors that affect the rework, it is likely to be helpless, even the best market outbreak may have nothing to do with you! Here we take 3 industries and will be analyzing its challenges and giving suggestions for them.

The automotive industry

The automotive industry involves a wide variety of customers, complex manufacturing processes, demanding supply chain processes, a wide range of personnel involved, a wide range of components, a wide distribution of suppliers, and many associated industries. Therefore, its supply chain is the most complex; coupled with the downward market pressure in 2018-2019, it was expected to increase some sales during this year, but it can be said that it suffered a huge blow after the coronavirus epidemic.

Automotive companies first need to analyze which areas and stores are likely to be the one to restart operating, recovering and boosting sales, and start needing to arrange distribution of new vehicles based on the epidemic and government control, thus boosting the capacity production of OEMs. At this point, forecasting and planning become particularly important, for the shipping plan, final assembly plan, material set plan, supplier arrival plan, etc. play a pivotal and driving role, specifically in the information technology pull through, big data real-time access, analysis and command operations, which will also become the enterprise supply chain whether the combat effectiveness of the watershed.

It is necessary to explain in particular: the automotive industry whether to be able to effectively deliver, parts suppliers delivery capacity will also become one of the key bottlenecks affecting the host plant on-time delivery. Although OEMs generally require parts suppliers to have 3-5 days of inventory, and about 10 days of inventory before the outbreak of Covid-19, the quarantine and postponement of work brought about by the epidemic have exceeded 15 days, which is a huge challenge for suppliers in terms of stocking, production, and delivery lead time; especially for some enterprises with single-source supply model, which at this time presents a great challenge. Huge passivity and risk (Tesla and Hyundai’s production shutdowns were largely due to suppliers’ short-term inability to meet production requirements, causing their stocks to plummet).

The food industry

The agriculture, fresh food, and restaurant chain industries are in fact part of the same supply chain. This supply chain is completely different from the manufacturing supply chain, which is « quick to sell, slow to produce »; it is also the industry with the most sensitive consumers and the least resilience to risk. The fresh food and restaurant chains have suffered heavily from the outbreak (and some have even faced extinction). As the quarantine ban is gradually lifted, consumer demand for food will explode. For agriculture itself, due to epidemic-induced chemical plant shutdowns and blocked logistics access, agricultural products have been hampered by the supply chain and cannot reach farmers on time, especially large-scale farmers who are farming without the protection of key agricultural products, which will greatly affect agricultural output.

It is recommended that the relevant enterprises and government departments, to plan ahead, advance planning of agricultural products supply chain in the future, to ensure the orderly supply of food production, so as to better protect the restaurant chain enterprises as soon as possible to resume normal business, enhance and effectively stimulate the consumer economy.

The furniture industry

Including home textiles, clothing industry, due to the customer’s individual needs are particularly pronounced, the enterprise reworking, even more, should not start from the factory (except for those with orders in stock). At this time, it is necessary to be aware of the inventory of stores and at the same time with the stores and dealers to do a good sales forecast for the next month (if there is a new seasonal product launch, need to synchronize promotion), accurate forecasts are conducive to the start of the product – production – capacity scheduling. Due to the long procurement cycle of key raw materials (cloth, cowhide, wood, etc.), the supply requirements for suppliers may not be the main bottleneck; however, due to the relatively low standardization of process and supply chain, relatively low level of production automation, and high experience requirements for employees, there may be some difficulty in recruiting staff, so it is necessary to do a good job in advance of the old employee recall plan and effective work. Arrangement. Companies with a better supply chain, at this time more likely to launch how to improve the service level for stores and distributors through their supply chain capabilities, improve the inventory – logistics – information interconnection between brands and distributors, reduce the opportunity cost caused by the dispersed capabilities of store guide sales staff, improve their ability to lead sales, accurate communicate the value of product development and take the opportunity to include distributors in the strategic path of their supply chain integration, thereby reducing the « bullwhip effect ».

What are the suggestions to make the supply chain stable after Covid-19?

Check the status of the order

A rolling review of the status of all purchase orders that have not yet been shipped is performed based on order data in the buyer’s system. This is based on every result of the verification at the SKU level of each order, the buyer can understand the order status in detail and make short term decisions.

Close contact with suppliers

Weekly calls to suppliers to check on their recent status and production plans. Due to the epidemic, we were unable to travel to the suppliers to check on the status and production plans. We can only find out by phone whether our orders have been placed in the supplier’s master production plan by doing an on-site survey at the supplier’s factory. Suppliers may have production constraints, such as a lack of raw materials and workers, poor logistics and transportation, and original lead times lead is likely to be extended, therefore, we also need to know how many days the updated delivery date will be added to the original date. According to a survey released by the Institute for Supply Management (ISM) on April 14, between March 17 and 30, the global average lead time for manufacturers has increased significantly, by 222% in China, 201% in Europe and 200% in the USA, which means that the lead time from order to delivery has at least doubled, and what used to be a one-month lead time is now at least two months.

Prepare sea shipment booking in advance

There are two main variables in booking, the first is the appointment to load the container and the second is the number of containers. Under normal circumstances, ocean freight booking cabins are guaranteed two weeks in advance, but three weeks in advance is required for special occasions. But we don’t have to book too far in advance. Since cabins booked for more than three weeks may be rejected by the shipping company.

DocShipper Info

DocShipper info : The cost of outsourcing apparently varies in different regions, remember to check the details among each area. If you have any questions remember to contact us!

Close communication with logistics providers

Actually we need to communicate closely with freight forwarders, customs brokers, and other logistics service providers on a daily basis. In addition to providing important freight forwarding services, we are also in close contact with the freight forwarders, customs brokers, and other logistics service providers. In addition to transport services, logistics service providers can also provide up-to-date market intelligence, including congestion at the ports of origin of the various transport routes, as well as transportation bottlenecks at the destination. In the midst of the outbreak, some multinational freight forwarders regularly update their websites with reports on capacity resources in the market, including sea, air, rail, and air freight. This information gives shippers first-hand market information and can help them with transport options. This information gives shippers a first-hand view of the market and helps them to make informed decisions on transport options. We need to maintain daily communication with our logistics provider, mainly to discuss the status of urgent air shipments, the dynamics of the airfreight market. In international trade, where logistics and transport times are part of the delivery schedule, we need to calculate not only the supplier’s production lead time. It is also important to consider shipping times, which are aggregated together to be the full lead time. Adequate communication with the logistics provider is necessary to ensure accuracy in the delivery of information and eliminate unnecessary misunderstandings. If you want to contact with a stable logistics provider, contact us.

Use of air transportation to mitigate risks

In international trade, sea freight is the main mode of transport because it is the cheapest, while air transport is used only as a last resort. In the case of the epidemic, the shipping of containers was not possible due to trucking restrictions in some areas. However, during the epidemic, sea containers could not be transported on time due to restrictions on trucking in some areas. Transport to the port and the supply chain is at risk of breaking down. What was – a month’s worth of sea freight door-to-door time could be extended by two weeks. It becomes a month and a half, and there is a gap in the supply chain before the next ocean shipment arrives and there is a shortage of material to stop work. This is where we need to incorporate air transport into our risk mitigation plans and consider the use of air transport to compensate for deliveries extended by sea. Know more about the improvement of the shipping process in international trade.

FAQ |How does Coronavirus impact international supply chain?

Read more

Looking for more? These articles might interest you:

DocShipper info: Do you like our article today? For your business interest, you may like the following useful articles :

- Coronavirus (Covid-19) impacts on import/export business

- How does Coronavirus impact international supply chain?

- 💡How to find a good product to sell?

- How to find your reliable supplier for your business? [Fair Trade Guide]

- AliExpress | Use the Chinese panacea to sell your products online

- How a sourcing strategy can rocket your margin?

Need Help with Logistics or Sourcing ?

First, we secure the right products from the right suppliers at the right price by managing the sourcing process from start to finish. Then, we simplify your shipping experience - from pickup to final delivery - ensuring any product, anywhere, is delivered at highly competitive prices.

Fill the Form

Prefer email? Send us your inquiry, and we’ll get back to you as soon as possible.

Contact us