Since customer’s demand is becoming more and more stringent, companies are all experiencing an increase in customer expectations. This is why they are trying to improve their response time as for example Amazon has set the trend with its one-day delivery. The customers are no longer satisfied with the quality of their products and services, but they are perceiving each purchase as an unique experience and we are sure that you noticed that in your customer’s feedback.

Today we are going to see how can the packaging be improved to reach those new expectations, and if it is concerning only final consumers or also BtoB customers.

In this new guide, our goal is to provide you with guidelines on what are the pillars of packaging and we will be able to help you on the themes of transport, storage, protection and preparation of your products, as well as on how to distribute them to your customers.

On the other hand, we will allow you to take a closer look at how your packaging can enrich the customer experience and contribute to improve your CSR approach.

NEW TRENDS IN DOING BUSINESS ARE CHANGING PACKAGING STANDARDS

Packaging standards are taking a new dimension and seeing their world-changing since e-commerce, as well as omnichannel distribution and e-commerce strategies, have been developing strongly.

Customer demand to live new experiences and their environmental concerns gave rise to productivity optimization, reverse logistics. These new trends are sources of innovation in the packaging industry.

Basically used for a variety of purposes such as protection and security of the product.

It actually became a key tool in customer relationships and reflect the image of the brand.

Packaging can be an underestimate tool that brings real added value to the experience of the customer but not only, indeed it can be also a lever in optimizing your logistic costs. It is a key point in your company’s strategy.

Today we will address, among other things, the different steps to choose the right packaging to fulfill the protection needs but also contribute to transport optimization, storage space, product use and environmental preservation.

How to protect your merchandise ?

How to guarantee qualitative and resistant packaging, adapted to delivery method ?

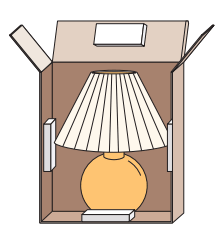

When thinking about the primary function of packaging, the first answer coming is to ensure the protection of the goods so that they can be received by their recipient in good conditions.

The two obvious factors to consider are the weight and fragility of the product which are determining the needed resistance of the package and the type of cushioning to be used.

However, the first packaging’s external criteria is the shipping method and the number of delivery breaks that your shipment will undergo between your warehouse and the final customer !

To optimize the quality of your packaging while providing the best possible protection, two alternatives are available :

Either you opt for a standard case and focus on the volume or you choose a more resistant case and reduce the volume.

1. Preserve the merchandise from eventual shocks

During the delivery of your merchandise, and with the different steps through which your goods are passing by, packaging has several occasions to show its necessity.

Indeed, depending on the transport’s mode you’re using, the damages could be very variable with for example a really careless handling of the goods during delivery breaks, because even if there is pallets an accident can happen, that’s why the choice of the external packaging and the made to measure package adapted to the dimensions of the product are essential to limit the risks.

When talking about cushioning we need to present its two functions : the prevention of a movement from the product and avoiding external and internal shocks between two products.

One of the trends in this area is the adapted foams which are totally adapted to the exact shape of the products.

2. Protect the goods from external conditions.

Before your goods arrive at his final recipient, the packages will be subjected to a number of moves during being loaded and unloaded with potential careless attention. This is why the packaging must be resistant as it is the only barrier to the product.

The lightest packages are not always on top of the heavier ones so you have to be proactive and create the perfect packaging for your goods by personnalizing it for examples with our sourcing agents help. Do you imagine a situation where you put efforts into the product quality, where your shipping process is efficient but your final products arrive damaged? No! Because it would be the worst scenario and you could just blame yourself, you have to be sure when choosing your packaging.

You obviously have to consider the vertical compression strength but it is also necessary to anticipate external conditions such as the meteorological risk upon the transport, humidity in the warehouse, shipping, etc.

![]()

There are many choices to protect your products depending on their type. For example, food and pharmaceutical products need special treatment to be arriving in good conditions because they are perishable. The wide variety of protections is including between others, desiccant bags, anti-corrosion paper and film, tar paper, isothermal packaging guaranteeing the temperature variation indicators.

DocShipper Alert

Alerte DocShipper : A wet package is not something your customer can accept, and he will be frustrated and upset by asking for a second shipment, you don’t want him to associate your brand name as these words.

How to improve your expedition process

Ensure the best transport conditions for your goods

The product is packed, secured and is now ready for shipment but you have to make sure that you’ve taken the destination, tariff rules, and type of transport for this particular good.

Whether the transport is invoiced by weight or by volume, the choice of the box and the cushioning is determinant.

1. Lighten the packaging and cushioning

In some countries, the rate for shipping parcels is calculated according to the weight of the package. However, it is a real challenge to find a good ratio between the necessary cushion and the overload of the parcel taking into consideration that you still have to ensure goods protection.

As said previously we gonna expose you two options :

- Opt for a standard quality box, increasing the cushioning at the same moment.

In this case, the packaging costs is gonna be higher because your shipment will cost more.

- Opt for a resistant box limiting the cushioning materials.

The cost of the box are logically higher, but the transport costs are reduced because of the lower storage volume( More boxes on the pallets, lighter weight of each box).

2.Understand the weight/volume ratio

1kgs feathers weight the same as 1kg lead. That’s what we all heard since we are born right ? Today we gonna tell you how it is not applicable to logistics.

The two main factors that are gonna determine the final cost of a shipment are the weight and the volume of it. In transport and logistics the weight/volume ratio is the parameter that is supposed to be used to calculate the price. Of course, it is different for each transport method. Let’s look at the field of road transportation which ratio has been commonly agreed on 1:500 and it is considered as a reference, so it’s assumed that a cubic meter of goods weights 500 kg.

Transport rates are calculated based on the greater of the total weight or actual weight of the total volume (called also “taxable”) of all the packages part of a shipment. The taxable weight is calculated by multiplying the volume of the package with the weight-volume ratio considered by the type of transportation.

To control transport costs, it is therefore essential to adjust the size of the package to the goods it contains and to think its shape to be able to ban unnecessary voids.

DocShipper Tip

DocShipper Tips : As we know, it is sometimes hard to understand the Volumetric/ weight ratio, so as we wanted to save you time, we are giving you the different ratio per type of transportation.

- Air freight : 167kgs/ CBM

- Express freight : 200kgs/CBM

- Sea freight : 500kgs/CBM

- Truck freight : 100kgs/CBM

DocShipper Tip

DocShipper example :

- 10 packages, total weight kg. 3.500, dimensions of each package 120 x 100 x 80 cm.

- The volume of the shipment is 10 x 120 x 100 x 80 = 9.60 m3

- The taxable weight is then 9.60 m3 x 1,000 = 9,600 kg > 3,500 kg

- The shipment cost will be calculated on the chargeable weight of 9.600 kg

Thinking about your packaging in terms of transport

One of the transport challenges is to ensure the protection of your goods throughout the shipping. Considering the different potentials risks for your goods, you have to know what treatment give to them. If you send a low volume of packages and do not palletize it yourself, then, one possibility is to get them onto a courier’s pallet where your packages will be protected by the palletizing film during the duration of the shipping.

Choose boxes compatible with standard pallets, checking the quality to avoid potential crushing for example if your merchandise is shipped in a LCL container.

As usual, make sure to optimize the dimensions according to the

mode of transport: which can be road, air, trail, sea.

The material of the pallet has an influence on your shipping costs.

- If your merchandise allows it, you rather choose molded wood pallets which weight is lighter but above all easier to handle in comparison to other pallets such as wooden ones. On top of that, they are not submitted to a heat treatment for the pest, and disease proliferation before export, unlike the wooden pallet, which is requiring an ISPM15 certificate of compliance for export.

The essentials rules to respect when palletizing different sizes of boxes.

– The smaller boxes should be placed at the bottom when the largest ones should be placed at the top of the pallet.

– You can improve the strength of the pallet by the use of stretch film, spacer plates and corner protectors.

– You should always use additional protection for the security of your loading with for example a cover protecting the pallet from bad weather a nontransparent film that prevents seeing what is in your pallet.

Enhacing your packages and pallets protection

The cost of securing your shipments depends mainly on the value of your merchandise is determining the security price of the shipment but the shippers also determine it depending on the break-in average rate for this particular type of goods. Because we usually don’t think of, it let’s remind you the hidden cost of a theft. The loss of the product is a synonym of a new shipment and do not forget the cost of the eventual customer dissatisfaction!

Some type of products are regularly being stolen. here are the first 5 categories of products which are usually stolen.

1. Safe boxes : The cardboard should be thick and use the design of the case shoulb be significantly contributing to security. For example you can use a flap crate added to a reinforced bottom and cover and double the thickness of the cardboard to prevent from passing the hand inside.

2. Adhesive : A personalized adhesive with a special positionning, makes the closing of your packages unique, and allows you to verify that the package has not been manipulated during any of the logistic phases.

3. Security closures : You can adopt various devices to provide evidences that the package of the goods has not been manipulated for the all duration of the transport. One of them is the gummed tape, which is very difficult to tear off, and which is visible if touched. High security adhesive leaves a break-in message.

Save storage space

How to store packaging efficiently

Select the packages you wanna use according to the caracteristics of your merchandise, because saving space can have a beneficial influence on your cash flow and on your storage space. This will probably require testing different alternatives, but in a long term perspective, it will allow you to gain a lot. You can also opt for space saving solutions and adjust the production of your cushioning on demand. You can also take advantage of a just-in-time supply, which will give you a great flexibility.

Saving storage volume

The different types of packaging you are using in your daily operations should always remain available because it is impossible to imagine that your products are not ready to send because of the lack of packaging.

However, even if storing can represent a certain volume in your all storage space, you should find the perfect combination between having enough packaging or having too much. On top of that, depending on the variety of product, it can be more complicated when you have differents types of packaging for each reference.

There are and this is not well unknown – variable height cases which can be adjusted thanks to a simple cut on the corners. You can find many different references on Amazon, they are easily modulable and providing up to 12 different heights. The telescopic cases are also a good option which are adaptable in height allowing to optimize the height of the cases.

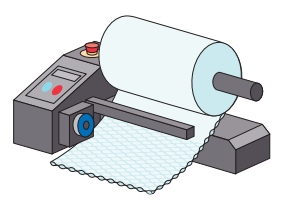

Produce cushioning on demand

The most traditionnal cushionning mode are polystyrene cushioning, particles or traditional bubble wrap, are cumbersome and hardly compressable.

If you are aware of your packaging needs, you can invest in a system that produce cushioning on demand, using consumables that are extremely compact and easy to store. The advantage is that you never have a full stock which would occupy a lot of space at the beginning of the stock, in this case you would just have the necessary amount of packaging.

Solutions to save space

Another way to gain space is to use stackable pallets. You can find pallets of these types for each pallets material like cardboard, molded wood or plastic, and as you imagine, they’re a good solution to save money and space.

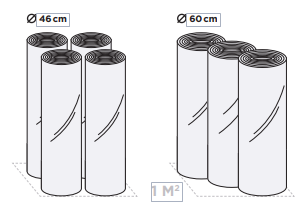

Consider also space-saving bubble films solution which is 25% less voluminous than a standard roll of 50 micron film, and they offer a comparable resistance thanks to the strength to the reinforcement of a nylon film.

Just-in-time packaging supply

You maybe are selling your products this way, so you have to be aware your packaging suppliers may have this option too. If you know how to manage this supply form, and make sure to respect deadlines, then the just-in-time solution is a great way to gain space. You order the right quantities for the week or the month and make sure that your cash flow is not immobilized.

Accelerate the preparation of your orders

How to win efficiently when preparing orders

Your productivity is affected by the right packaging choice because it can be a way to fasten the preparation of orders. Indeed, if you can adapt your packaging process with automation, you will be able to handle even higher quantities.

Optmizing productivity by a more rigorous and reliable productivity

The time spent on order preparation is a key element in the results of your logistics costs and can be optimized at his maximum which is what every company is looking for.

The technology evolution have been changing the productivity of the packing stations and it is now possible thanks to machines to quantify it.

Thanks to these machines, it is possible to calculate the preparation time and therefore the number of packages per day. These productivity numbers are helping to obtain a better control of the rates and are allowing production in parallel time: once an operator has started a machine, he can be working on other machines or tasks. Technology contribute to increasing productivity.

Solutions to automation

The automation of the packaging station is possible in many cases, because the companies are trying to obtain a simple packaging solution for their customers. The most known and used ones are :

– Pallet wrapping machines

– Strapping machines

– Bar code scanners

– Automatic closing systems

DocShipper Tip

DocShipper Tips : You are looking for automatizing your packaging process and you’re looking for machines such as wrapping machines ? Contact our sourcing agents thanks to our contact form, they will be able to help you find suppliers

The secrets of a good packaging

The creation and adaptation of your packaging are gonna be determined by various criteria which you have to shape by asking yourself a series of questions.

First, consider the nature of your product and its fragility.

If the product is perishable, needs special packaging conditions or is already packed, the final choice will be different.

- Nature of the product

Is it fragile, solid or liquid, sensitive to environmental conditions such as heat or humidity ?

This can determine your choice of packaging

- The transport conditions and potential delivery breaks

conditions to be taken into account immediately in the choice of

of the packaging that guarantees the integrity of your goods.

- Reduce the cost of transportation

Optimize the volume of your packaging reduces the weight by opting for example for the foam packaging, as close to the product shape.

- Value of your products

The value of your goods and the rate of theft concerning this type of product will determine the security devices you will need for your packages.

- Products and brand perception

The packaging must be aligned with the standing of your product because it will be the first thing your consumer will see. ( example: luxury products )

- Type of carrier

Either the product are on pallets or shipped by a courier service, the package is not gonna go through load breaks. The transport type you will choose is determinant.

Build up your customer’s experience!

The Packaging is a key element of your customer relationship because it incarnates the only physical contact in the distance purchasing process and its a way to bring loyalty from your clients to your brand. As it is supposed to represent your brand image and your values, you have a limitless choice of options and you should really not underestimate its power.

As soon as the package is received by the recipient, he will unconsciously analyze if it is easy to open, practical.

As the global trends tend to favorise environmentally friendly initiatives, the client will notice and prefer a recyclable type of packaging.

The personalization of your packaging will have a certain influence too on the feelings experienced by the target and it is close to be as important as the product.

This process mustn’t forget to take into account the potential ease of the return of the order.

Make it practical

For the consumer, convenience is a combination of several factors.

The package opening should look intuitive and with for example a tear strip, which makes it easy to open with hands and not like old-school adhesive which requires the use of a knife potentially damaging the scissors.

You should choose wisely your cushioning knowing that certain methods like filling the boxes with polystyrene can bring frustration to the client experience, while bubble papers are more appreciated.

The environmental impact of the packaging is know something to optimize and put forward because of the trends. Opt for a single material packaging which makes it easy to recycle.

Customization

Now that customers demand in personnalization are increasing, you should pay attention to details, create a correlation between your product and the packaging to impress your client, bring him into your universe.

if you don’t want to create it from scratch you can source some ready boxes and just add your logo on it many models are existing and companies are dedicated to this activity.

Cardboard boxes can also be customized.

One of the fashion that are now being developped are the personnalization of only the box interior, to create a surprising effect for the customer, as if he was entering in your brand world.

As it will create the gap between you and other companies, you should really consider this details and make tests by using samples thanks to the services of your sourcing agents.

Don’t forget the goods return

Clients opinion and willingness to buy again from you, is also influenced by the easyness to make a return and be in contact with you. Many companies like UPS are now putting a return kit inside to simplify this eventuality. It is of course easier for the client to use the original box to carry out the return of goods, it can also include a return label. A return kit can also be showing that you are trying to re-use packaging and be a proof of your environmental comitment.

DocShipper Tip

DocShipper tips : Are you interested in our sourcing services ? You need the advice of a specialized agent ? Our expert team will be pleased to help you, contact them thanks to our online form.

Brandish your environmental comitment

Improve your company’s environmental responsability

Consumers are nowadays caring more about the environment preservation. They will be sensitive and responsive to the actions of the brand towards ecological transition. If your business tends to protect the nature and is involved in its preservation they will be friendly and feel that they’re helping the cause. That’s why your packaging should comply or even be a innovation in terms of environmental initiatives. An adapted choice of materials is the best way to prove it. You really should show it to your client and make sure he will notice it.

Make recycling easy for your customer

Recycling is an increasingly popular way to reduce the environmental impact of distribution.

In this area too, it is important to encourage the customer to recycle the packaging you’re sending to him, or by making it a unique material package so he can just put it in a proper bin or like some companies, propose a way to use the packaging.

Packaging in CSR

Already many companies are using packaging in their CSR to prove their comitment to their customers. For example, Amazon and Ikea are already informing their customers about their packaging choices. It builds loyalty towards your brand and show you values.

Packaging in general has a bad reputation, but you can make it a strong argument to show your care about planet preservation.When it comes to corporate social responsibility (CSR), you must show your engagment by using eco-designed recyled materials, recovery channels. Don’t forget to communicate with your customers on all the aspects of your CSR process and how you are decreasing the impact of packaging on the environment.

What you should remember

A packaging is a reflection of the product it contains and but also of the image of the brand as a whole. It is common that many brands are conducting extensive research into consumer wants and needs to ensure that their packaging is the right one.

What you have to remember is that the packaging has differents fonction :

It is supposed to be part of design. Choosing a style and colors that will appeal to consumers and encourage them to pick up your product is very important, as is choosing high-quality packaging materials.

Size and shape of the packaging have to be different from the competition’s. The colors you choose for your packaging can easily help place your product apart from concurrence’s ones. Innovative designs will catch the client attention and help give your product a special distinction.

Your values should be clearly appearing and be understood throught the packaging, this is what could make a client understand with the first look that you’re engaged in environmental preservation cause. It can be shown or by the colors choice or by the materials you use but also by the potentials other functions of your packaging.

Finally, don’t forget that it can be a huge money saver lever because of the saved storage space it can bring when it is optimized. Now that you know everything about how to pack goods, you can begin to imagine and buy your packaging.

DocShipper Tip

DocShipper tips : You are interested in the our sourcing services ? You need advices from a specialized agent ? Our experts team will answer you within 48h contact them thanks to our online form.

FAQ | All you need to know on how to pack goods

Read more

Looking for more? These articles might interest you:

DocShipper info: Do you like our article today? For your business interest, you may like the following useful articles :

- Coronavirus (Covid-19) impacts on import/export business

- How does Coronavirus impact international supply chain?

- 💡How to find a good product to sell?

- How to find your reliable supplier for your business? [Fair Trade Guide]

- AliExpress | Use the Chinese panacea to sell your products online

- How a sourcing strategy can rocket your margin?

Need Help with Logistics or Sourcing ?

First, we secure the right products from the right suppliers at the right price by managing the sourcing process from start to finish. Then, we simplify your shipping experience - from pickup to final delivery - ensuring any product, anywhere, is delivered at highly competitive prices.

Fill the Form

Prefer email? Send us your inquiry, and we’ll get back to you as soon as possible.

Contact us