3PLs refers to the external suppliers providing all or part of the logistics services to the enterprises. The third-party logistics providers offer logistics services generally including transportation, warehouse management, distribution, etc.. In this process, the 3PL supplier is not the production side, nor the sales side, but the third party offering services in the whole logistics process from production to sales. It generally does not own goods, but only to provide customers with warehousing, distribution, and other logistics services.

If you are a newcomer to this industry, follow us to know more information!

The development of 3PLs

One of the outstanding achievements of the logistics industry in the 1990s was the widespread emergence of Third-party Logistics Service Providers (3PLs), which outsourced operations outside of a company’s core business (Outsourcing), which is always considered as a hallmark of modern, efficient supply chain management.

Third-party logistics has grown significantly in the United States over the past 10 years, with the United States 3PLs business growing 40% annually in 1997 and 15% in 1998, from $34.2 billion in 1997 to $39.6 billion in 1998.

Although 3PLs are seen as a new industry, integrating old industries such as transportation, warehousing, and packaging on the basis of information technology to provide a wide range of integrated services to other industries, in Europe, 3PLs is not a new concept.

Outsourcing as a business operation has been around for hundreds of years in Europe. Many well-known logistics companies, such as Schenker, Kuehne & Nagle, and Danzas, date back to the Middle Ages when they offered integrated services such as warehousing, transport, and customs brokerage. They still provide logistics services to the major European manufacturers, distributors, and wholesalers. The real rise of outsourcing started in the late 80s and early 90s, before the economic integration of Europe.

Until the late 1980s, the new European Distribution Centers (EDCs) built by American companies were operating on their own, but these companies found the need for more flexibility and different types of services to meet the needs of the new EU and they started to turn to outsource. As a result, the number of EDCs managed by third parties increased dramatically in the 1990s.

DocShipper Tip

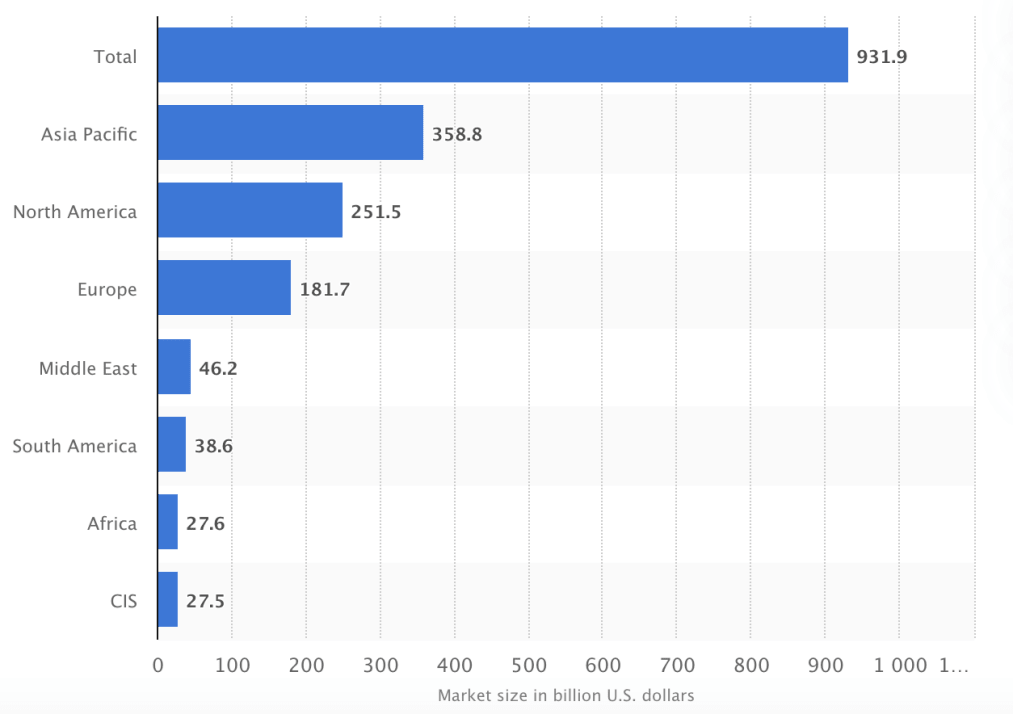

DocShipper Advice : Currently, the market share of 3PLs as a proportion of logistics costs varies around the world. In the United Kingdom, the proportion is as high as 35%; in the European Union, $129 billion of the logistics services market of $31 billion subcontracted to third-party logistics companies, about 25%; and in the United States, the ratio is less than 10%. According to UPS Global Logistics Services predicted that in Europe, the market share of third-party logistics companies in 2002 will reach 28%.

You should always keep in mind that DocShipper will always work on optimizing the logistic processes in order to maximize your results, your costs and will also support you throughout the purchasing process: supplier research, negotiation, quality control.

Why is 3PLs on the rise?

Research by the Outsourcing Institute in New York shows that 35% of 3PLs’ chief executive officers (CEOs) cite the primary reason for outsourcing as reducing operating costs, another 30% cite outsourcing to avoid investing in assets for non-core operations and activities, and only 17% cite outsourcing to improve service. Overall, there are several reasons why more and more companies are outsourcing their logistics operations to 3PLs:

(1) Reduction of operating costs

Generally speaking, 3PLs can reduce costs for corporations by at least 10%. This is the main reason why many companies are now opting for outsourcing. Especially in Europe, due to more taxes, higher labor costing and more regulations and operation restrictions, the logistics cost in Europe is twice as high as in the U.S. This is also an important reason why many companies choose to outsource.

DocShipper Alert

DocShipper Advise: You don’t have to worry about your logistical routing and the conformity of your electrical products, you can count on our 3PL (Third Party Logistics) to handle the entire process safely. Do not hesitate to contact our agents!

(2) Focus on core business

Modern competition theory holds that in order to gain competitive advantage, a company must consolidate and expand its core business, which requires it to focus on the development of its core business. As a result, more and more enterprises outsource their non-core business to specialized 3PLs.

(3) Reduce investment and make use of advanced technology of 3PLs.

The efficiency of the 3PLs’ logistics operations depends on their state-of-the-art facilities and software, and the use of 3PLs can reduce the huge investments made by enterprises in this area. A survey shows that 3PLs are investing heavily in logistics technology, including software, communications, and auto-awareness systems. 74% of 3PLs spent an average of $1.08 million on logistics technology, barcode systems, another $610,000 on software, and $400,000 on communications and tracking equipment. In addition, 60 percent of the 3PLs purchased material handling equipment for their customers, spending $0.41 million on shelving, $0.45 million on storage and retrieval systems, $0.30 million on dock equipment, and $0.43 million on cranes and accessories.

(4) Re-integration of the supply chain

There is a growing trend for companies to outsource the entire process, not just logistics to 3PLs. Compaq, for example, uses a vendor-managed inventory management system with its suppliers, which reduces the supplier’s investment by hiring CTI to perform key processes such as inspection, quality assurance, inventory management and to provide logistics services. The shift to process management is one reason why more shippers are paying per unit, where the 3PLs are paid on a per-unit basis for each product produced by the customer, which presents both risks and opportunities for the 3PLs to consider whether they will be paid more than their fixed and variable costs. The same consideration should be given to manufacturers when they choose to outsource. Find outsourcing regulations.

(5) Expanding international business

With the acceleration of global economic integration, many companies without international marketing channels want to enter foreign markets, and international 3PLs can help these companies to achieve the purpose of expanding their international business. For example, Santa Cruz, R.S.V.P., a company that uses recycled materials to produce a special kind of packaging, this kind of packaging is designed for sophisticated high-tech goods and design, Santa company using 3PLs-Circle trade services to successfully expand the international business.

(6) The need for corporate virtualization

Virtual companies and e-commerce are seen as the most promising business models of the 21st century, however, the success of virtual companies rely on 3PLs.

The staff at Ensemble is dedicated to product innovation, identifying market needs, developing products, and then providing ideas to retailers before they go into production. In short, Ensemble is in the business of creating and delivering solutions tailored to market needs. As a virtual company, Ensemble relies on other companies to perform other traditional business functions, such as manufacturing and distribution. In the beginning, Ensemble outsourced manufacturing and sourcing. Today, Ensemble uses hundreds of suppliers around the world for manufacturing but has only one partner in distribution-USCD Distribution Services, a company founded in 1967 to provide value-added logistics services. Under the agreement, USCD handles all of Ensemble’s order fulfillment, receiving goods, warehousing, and shipping within the United States. Ensemble receives orders from more than 4,000 customers in the U.S. On average, 100 shipments per day are shipped to Hallmark’s independent card, grocery, and other retail locations. Ensemble receives orders from more than 4,000 customers in the U.S. These orders are transmitted to Ensemble by phone, fax, or EDI, and Ensemble transmits them via computer to USCD for order fulfillment. In addition to its traditional warehousing and shipping responsibilities, USCD also provides distribution consulting services to Ensemble.

What are the basic characteristics of the 3PLs?

A package of services-oriented by the contract

Unlike traditional outsourcing, which is limited to one or a series of dispersed logistics functions, such as transportation services provided by transport companies or warehousing services provided by warehousing companies, 3PLs provide multi-functional or even all-round logistics services based on the requirements specified in the terms of the contract, rather than temporary requirements. In accordance with international practice, the service provider charges 20% of the cost of logistics provided plus the gross profit of the demand side over the term of the contract.

Personalized logistics services

3PLs service objects are generally fewer, only one or several, but the service time is longer, often as long as a few years, which is different from public logistics services. This is because the demand side of the business process is different, and logistics, information flow with the flow of value, thus requiring 3PLs services should be customized according to the customer’s business process, which also shows that the theory of logistics services from the “Product Marketing” to “Market Marketing” Phase.

Based on modern digital information

The development of information technology is a necessary condition for the emergence of 3PLs. Information technology realizes the fast and accurate transfer of data, improves the automation level of warehouse management, loading and unloading transportation, procurement, ordering, distribution and shipping, and order processing, and realizes the integration of ordering, packaging, storage, transportation, circulation, and processing. Enterprises can more conveniently use information technology to communicate and collaborate with logistics enterprises, and the coordination and cooperation between enterprises can be improved. Cooperation is possible in a short period of time to be completed quickly.

At the same time, the rapid development of computer is so fast that the costs which are mixed in other business activities in the logistics can be accurately calculated, as well as effective management of logistics channels in the flow of commerce, which makes it possible for enterprises to complete the original internal operations with the logistics company operation. The technology commonly used to support the 3PLs of information technology: EDI technology to achieve rapid exchange of information, technology to achieve rapid payment of funds, technology to achieve rapid input of information barcode technology, and online transactions to achieve e-commerce technology, and so on.

Alliances between corporations

Relying on the support of modern information technology, the enterprises of 3PLs fully share information with each other, which requires mutual trust between the two sides. In order to achieve better results than the logistics activities alone, and from the principle of logistics service providers’ fees, they share the risk and benefits; moreover, the connection between enterprises is not just one or two market transactions, but also in the maintenance of the transaction. After a certain period of time, you can replace each other’s trading partners, each does not completely make actions that lead to maximizing their own interests, nor completely make actions that lead to maximizing common interests, but through the contract to form a comparative advantage, risk sharing, two-way or multi-directional flow of elements of the intermediate organization in logistics, therefore, enterprises are the logistics alliance relationship.

DocShipper Info

DocShipper Advise: The cost of outsourcing apparently varies in different regions, remember to check the details among each area. If you have any questions remember to contact us!

The merits and demerits of 3PLs

What are the advantages of 3PLs?

Firstly, it enables companies to concentrate on their familiar business and allocate resources to their core business. Apparently, enterprises can concentrate on their core business as well. As the resources of any enterprise are limited, it is difficult to become an expert in all aspects of the business. Thus the enterprise should allocate its main resources to focus on its main business, and leave the logistics and other auxiliary functions to logistics companies. For instance, one of GM’s plant achieves good results through the professional logistics company Ryder’s cooperation, while it concentrates on automobile manufacturing, Ryder manages its logistics affairs. In this way, it applies special decision support system software to efficiently plan routes and minimize transportation costs.

Secondly, the flexible use of new technologies to achieve the information in exchange for inventory and reduce costs. When science and technology advances, professional 3PLs can constantly update information technology and equipment, while ordinary single manufacturing companies usually have difficulty in updating their resources or skills; different retailers may have different, changing distribution and information technology needs, at this time, 3PLs can meet these needs in a fast and more cost-effective way, and these services are usually out of the ability of only one manufacturer. Likewise, 3PLs have the ability to meet the needs of an enterprise’s potential customers, thus enabling the enterprise to approach retailers.

Thirdly, it can reduce the investment in fixed assets, accelerating capital turnover. Enterprises need to invest a lot of money to buy logistics equipment, build warehouses and information networks, and other professional logistics equipment. These resources are a heavy burden to enterprises lacking capital, especially SMEs. The use of 3PLs not only reduces the investment in facilities but also frees up the capital occupied by warehouses and fleets, which accelerates the capital turnover.

Lastly, it is able to provide flexible customer service to create more value for your customers. If you are a supplier of raw materials and your customers require rapid replenishment of their raw material needs, you need a regional warehouse. With 3PLs warehousing services, you can meet your customers’ needs without having to allocate capital and operating flexibility for new facilities or long-term leases. If you are a supplier of end products, using 3PLs also allows you to offer your end customers a wider variety of services than you could provide to them yourself, adding value to your customers and increasing customer satisfaction.

What are the challenges of 3PLs?

While 3PLs provide the above-mentioned convenience for enterprises, there are also some challenges at the same time.

Firstly, they cannot directly control the logistics function, and as a result, cannot guarantee the timeliness and accuracy of supply or the quality of customer service.

Secondly, the solutions designed by 3PLs are usually tailor-made for different customers and are not widely applicable. Therefore, 3PL companies do not have economies of scale. 3PL companies reduce the cost of delivery for customers while the management cost will rise, thus the final cost savings for enterprises sometimes can be limited.

Thirdly, traditionally, companies have been able to meet the growing needs of their customers by optimizing inventory and utilizing regional service agents and 3PLs. Now, however, customer needs services including e-procurement, order processing capabilities, virtual inventory management, and more. Businesses are finding that some of the 3PL providers lack the comprehensive skills, integrated technologies, strategies, and global expansion capabilities that are currently required.

DocShipper Tip

Docshipper Tip : If your company needed a 3PL help, try to contact with a professional and stable agency like Docshipper.

What are the future prospects of 3PLS?

The development of 3PLs in future is very broad, and its business expansion will mainly come from the following areas of demand:

(1) Outsourcing of other businesses to regular customers.

Currently, the business undertaken by 3PLs is mainly focused on the most basic logistics services, such as transportation and warehousing. After the success of these operations, corporations often consider further expanding the scope of cooperation, such as product packaging, label printing, and even product assembly.

(2) Integration of supply chain operations

Integrated supply chain management requires companies to integrate the entire supply chain process, and 3PLs are experts in the field and can do this better than manufacturing companies. As a result, more and more companies are considering working with 3PLs to integrate their supply chain.

For example, UPS Worldwide Logistics (WWL) and Fender International, the giant arm of the guitar manufacturing industry, have partnered. UPS, based in St. Albans, UK, is helping Fender streamline and centralize its distribution process, enabling Fender to double its sales volume across Europe in recent years. UPS manages land and sea shipments from manufacturing plants around the world, while a third-party logistics company manages the inventory of its EDCs. Employees of the EDCs check product quality, review inventory, fulfill orders from distributors and retailers, and manage multi-carrier deliveries. By using UPS’s centralized distribution centers, Fender is able to shorten delivery times, better monitor quality and deliver orders, and more importantly, UPS tunes each guitar before it is shipped to the retailer to ensure that it is ready to play when the retailer takes it out of the box.

(3)Develop logistics information management system

With the integration of supply chains, corporations need information technology to support logistics operations. And corporate IT departments are busy with internal information systems, which provides opportunities for 3PLs to expand their operations. 3PLs have a clear advantage in logistics optimization and can help their customers to adopt supply chain strategies to manage logistics.

(4) Handling of uncompleted supply chain tasks

Returns and product packaging. It has become a basic principle in the supply chain management system to complete products as close as possible to the consumer or the buyer.

For example, UPS Worldwide Logistics (WWL) and Fender International, the giant arm of the guitar manufacturing industry, have partnered. UPS, based in St. Albans, UK, is helping Fender streamline and centralize its distribution process, enabling Fender to double its sales volume across Europe in recent years. UPS manages land and sea shipments from manufacturing plants around the world, while a third-party logistics company manages the inventory of its EDCs. Employees of the EDCs check product quality, review inventory, fulfill orders from distributors and retailers, and manage multi-carrier deliveries. By using UPS’s centralized distribution centers, Fender is able to shorten delivery times, better monitor quality and deliver orders, and more importantly, UPS tunes each guitar before it is shipped to the retailer to ensure that it is ready to play when the retailer takes it out of the box.

(3)Develop logistics information management system

With the integration of supply chains, corporations need information technology to support logistics operations. And corporate IT departments are busy with internal information systems, which provides opportunities for 3PLs to expand their operations. 3PLs have a clear advantage in logistics optimization and can help their customers to adopt supply chain strategies to manage logistics.

(4) Handling of uncompleted supply chain tasks

Returns and product packaging. It has become a basic principle in the supply chain management system to complete products as close as possible to the consumer or the buyer.

How do 3PLs develop from the traditional industries?

At present, the world’s third-party logistics enterprises are facing a period of rapid development, all kinds of enterprises of different backgrounds have transformed logistics or third-party logistics as a new growth point. It can be seen through the practice at home and abroad, third-party logistics enterprises are generally from the traditional development of logistics-related enterprises, such as warehousing, transportation, and so on.

Originated From the transport industry (shipping, road, rail, air)

Although no accurate statistics are available till now, third-party logistics developed from the transportation industry should account for the largest share of the market. The express and courier companies, mainly inland and air transportation, have developed into third-party logistics companies such as UPS, FedEx, TNT, DHL, etc.; logistics companies developed from maritime transportation include Damco Logistics and American Logistics.Originated From warehousing enterprises

Like the transportation aspect, warehousing is one of the most important aspects of logistics activities. As a result, many companies offering public warehousing services also offer integrated logistics services to their customers through functional extensions. In Europe, companies like Tibbett and Britten have evolved from public warehousing into third-party logistics companies. The transformation of China‘s public warehousing industry into a logistics company is also relatively obvious, such as the establishment of Shanghai Commercial Logistics Company by Shanghai Commercial Storage and Transportation Company to engage in the third-party logistics business.

Originated from freight forwarding companies

There are many freight forwarding companies transformed into modern logistics enterprises, such as Emery, BAX, MSAS, Schenker, AEI, Circle, and so on. As a result of the development of information technology and the maturity of the e-commerce environment, the profit of the freight forwarding enterprise becomes lower and lower. The freight forwarding business, based on the development of third-party logistics, has become the hotspot of the development of the freight forwarding industry.

Originated from the shipper

This type of business has evolved from the logistics organizations of large companies. They use their logistics expertise and certain resources, for instance, information technology, to provide third-party logistics services, such companies are Caterpillar Logistics (from Caterpillar Group), IBM Logistics, and others. Such companies now are also growing and have become highlights in the logistics market. For example, Haier Logistics, formed by the Haier Group, and Ande Logistics, formed by the Midea Group, are typical of shippers engaged in third-party logistics.

Financial and information consulting services companies

Integrators who were originally focused on building systems, in order to add more value to their clients, have also taken the initiative to provide work related to e-commerce, logistics, and supply chain management, such as Accenture, GE Information Services and so on.

Port terminals, railway stations, train stations, bus stations, air cargo terminals, etc.

These enterprises are based on the advantages of terminal operations, and extend their business to transportation and distribution. PSA started to invest in the logistics industry in mainland China in 1997, and its larger logistics projects include Shanghai Merchants Xingang Logistics Co.

Electronic distributor

Parts distributors and value-added service distributors are also entering the logistics value-added services arena. Their services include system configuration, EDI, shipment tracking, information system integration, inventory management, and so on. Typical companies include Arrow, Avnet, Syn-nex Techn. and Serial Systems.

The strategies of 3PLs

Enterprises should make strategic choices and strategic adjustments in cost control, business development, rational competition and other aspects.

(1)Cost leadership strategy

Cost leadership strategy refers to when the enterprises and competitors to provide the same products and services, the only way to ultimately win in the market competition is to make the cost of products and services for a long time below the cost of competitors. For third-party logistics enterprises, it is necessary to share the management and information system costs by establishing an efficient logistics operation platform. In an efficient logistics operation platform, when joining a customer with the same demand, its impact on the fixed cost is almost negligible, natural cost competitive advantage. Generally speaking, the logistics operation platform is composed of the following parts: the stable business volume formed by the customer group of considerable size, stable and practical logistics information system, extensive coverage of the network of business areas.

(2) Centralized strategy

Based on their own advantages and the external environment, enterprises should determine one or several key areas, concentrating enterprise resources, open business breakthroughs. Concentration strategy not only refers to the concentration of business development director but also requires enterprises to concentrate on the recruitment and training of human resources, the establishment of organizational structure, and the acquisition of relevant operating capital. Corporations should fully grasp the market opportunities, the effective use of the existing resources of enterprises.

(3) Enterprise alliance strategy

On the one hand, the enterprise alliance refers to a third-party logistics enterprise alliance; On the other hand, it refers to the logistics enterprises and shipper enterprises should establish a strategic partnership. Through the establishment of logistics alliances, building information-sharing platform, integration of the core competencies of enterprises, the enterprises can be able to seek the ideal road to of a win-win situation.

What is the best choice when choosing one to collaborate?

When it comes to the choice of the 3PLs, as we mentioned that we will encounter a lot of predicaments since we can’t guarantee the service quality and reliability of them, we should be careful about every aspect. DocShipper has launched a 3PL department to complete its supply chain offering. Indeed, we manage your entire process in case you are a newcomer in this industry. Supply: Supplier search, product negotiation and production follow-up (in Asia), Quality control: Inspection of the products to ensure that the quality is in line with your expectations, we also check the packing if necessary. Compliance: Verification of the various directives and licenses required during customs clearance and distribution. International logistics: Our forwarding department manages the chartering of your products (packaging, storage, sea/air freight, customs clearance). 3PL Solution: Our warehouse in Northern Italy (Camporosso) allows us to distribute your products at unbeatable prices! (Special E-Commerce). By managing the entire logistic part for you, you can take care of the marketing and sales. Your concerns become ours, serving your benefit. Know more information.

FAQs about how to find the best supplier

Read more

Looking for more? These articles might interest you:

DocShipper info: Do you like our article today? For your business interest, you may like the following useful articles :

- Coronavirus (Covid-19) impacts on import/export business

- How does Coronavirus impact international supply chain?

- 💡How to find a good product to sell?

- How to find your reliable supplier for your business? [Fair Trade Guide]

- AliExpress | Use the Chinese panacea to sell your products online

- How a sourcing strategy can rocket your margin?

Need Help with Logistics or Sourcing ?

First, we secure the right products from the right suppliers at the right price by managing the sourcing process from start to finish. Then, we simplify your shipping experience - from pickup to final delivery - ensuring any product, anywhere, is delivered at highly competitive prices.

Fill the Form

Prefer email? Send us your inquiry, and we’ll get back to you as soon as possible.

Contact us