Managing the complex process of manufacturing in China in 2024 requires a strategic approach. China is considered a global manufacturing powerhouse and continues to attract companies seeking efficient and profitable manufacturing. This survival guide provides essential information and practical advice tailored to today's business environment. As a sourcing expert, DocShipper aims to provide manufacturing companies with all the knowledge they need, from supply chain complexities to cultural considerations. Join us as we explore the key factors shaping the dynamic Chinese market and ensure you thrive in this evolving manufacturing and trade environment.

Manufacturing in China: market overview

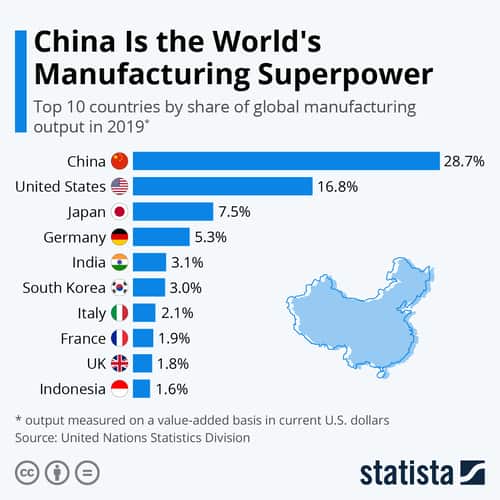

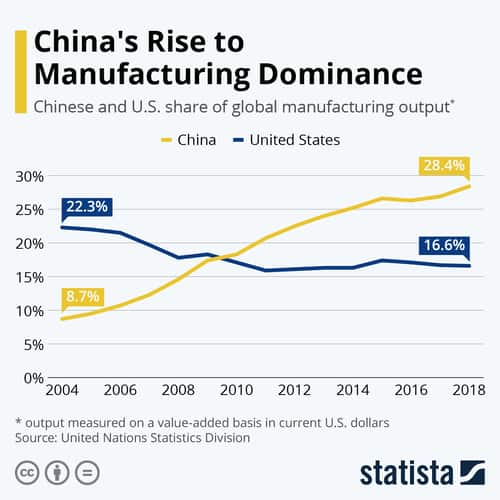

In the global manufacturing landscape, China has maintained its dominant position, securing the top role for over a decade and showcasing remarkable development throughout diverse sectors. Alongside China, other major players, such as the United States, Japan, and Germany, form the pinnacle of the 10 international locations leading in international manufacturing. These countries play an important role in the worldwide economy. As we delve into 2024, information on how those leaders impact the worldwide manufacturing panorama is essential. This exploration consists of a focus on China, the leader since 2019 with 28.7%.

This diagram illustrates the distribution of the world’s manufacturing giants in numbers, hence showing the top 10 international locations in 2019.

Navigating the complicated landscape of manufacturing in China involves key expertise. Now, let's delve into the important procedures and insights for a success production.

Determine your needs and map them

Items Successfully manufactured in China starts with a proper knowledge of your particular necessities/needs and a strategic mapping of the product process. Start by defining your needs in terms of a product, especially if it's your first adventure.

Remember to start with a less difficult item. Once your concept is solidified, verify its profitability by listing all prices and implicit profit sources. This complete assessment will guide your decision-making while selecting which way is most suitable to produce your product in China. Additionally, estimate the minimum unit quantity (MOQ) desired for profitability. This visionary method, no longer guarantees a coherent production plan ; however, it presents readability based on implicit gain.

Have a Product specifications sheet

A complete product specification sheet is critical to this process. It acts as a proper guide, detailing product dimensions, materials, layout specs, and quality standards.

This file helps share particular knowledge among you and the manufacturer, minimizing the risk of errors and production mistakes. Include precise production requirements, regulatory compliance details, and packaging possibilities to ensure seamless collaboration. By making an investment in a well-crafted specs sheet, you lay the basis for a successful collaboration and the adequate production of a product that aligns perfectly with your needs.

Find a manufacturer in China

Finding a reliable manufacturer in China is a pivotal step in bringing your product to life. In the great panorama of Chinese manufacturing, finding the right producer is a critical step for companies in search of quality products. Navigating through this complicated realm requires strategic insights and reliable sources. Trade magazines, wholesale marketplaces, and different structures play a pivotal role in connecting companies with reliable manufacturers, providing a wealth of information and options. Let's delve into those resources to empower your search for the right manufacturer in China.

Look to wholesale marketplace

Exploring wholesale manufacturing in China, through platforms like Alibaba and Global Sources proves to be strategic for product sourcing. These structures offer a multitude of suppliers, allowing green surfing and the assessment of numerous merchandise and manufacturers. Serving as a one-prevent solution, those systems facilitate charge comparison, product assessment, and supplier review. Utilizing that equipment gives valuable insights into a manufacturer's capabilities, manufacturing capacities, and typical reputation.

DocShipper info :Navigating the world of wholesalers may be daunting, given the multitude of alternatives available. DocShipper steps in to streamline this process for you. We meticulously pick out the pinnacle of B2B wholesalers, tailor-made to fulfill your precise needs in terms of product type, quantity, and delivery time.

For a hassle-free sourcing experience, reach out to us, and our experts will guide you.

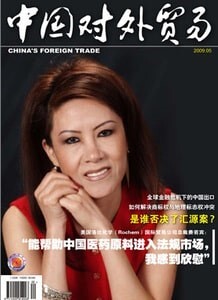

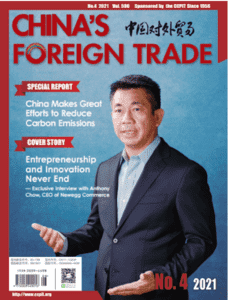

Trade magazines

Trade magazines serve as valuable sources since they help each company get -specific insights and connections in the manufacturing and trade fields. These guides provide high-intensity facts on trends, marketplace dynamics, and key players. In this context of finding manufacturers in China, trade magazines offer articles, advertisements, and client’s reviews to become aware of authentic suppliers.

Regularly reading, following, and subscribing to these magazines keeps you up to date on manufacturer and supplier trends, new updates, plans, and meetings. Additionally, they function as a networking tool, providing advertisements from producers and suppliers targeting clients.

Trade Shows: the best place to discover networks of manufacturers

One of the best ways to find a manufacturer in China is by attending the most popular trade show in China.

Here is a small list of the best and most famous trade fairs in China:

| Chinese fair / trade show | Localization | Period |

| Canton Fair (China Import and Export Fair) | Guangzhou | April-May |

| CIIE (China International Import Expo) | Shanghai | November |

| CIOE (China International Optoelectronic Exposition) | Shenzhen | September |

| Yiwu Commodities Fair | Yiwu | October |

| CHINA PEC (China International Exhibition for Petrochemical Technology and Equipment) | Beijing | Held biennially |

| ITMA Asia + CITME (China International Textile Machinery Exhibition) | Shanghai | Every four years. |

| China Beauty Expo | Shanghai | May |

| Beijing Auto Show | Beijing | Every 2 years |

| Shanghai Auto Show | Shanghai | Every 2 years |

| SIAL China (food and beverage expo) | Shanghai | May |

10 Top Fairs and Trade Shows in China: location and periodicity

For example, The Yiwu Commodities Fair, held annually in Yiwu, Zhejiang Province, China, stands as one of the most influential exhibitions for daily consumer goods and commodities. With a diverse showcase, spanning household items, textiles, electronics, and accessories. Typically, it takes place in October.

Still, if you're unfit to attend a trade show in China, there are trade shows in the United States that Chinese manufacturers attend. Trade shows are an inconceivable way to meet prospective manufacturers face to face, get information from them directly, and compare suppliers in person.

Chinese Markets

Chinese markets are multifaceted and imperative for manufactured products. These markets embody a diverse variety of suppliers, presenting alternatives for sourcing substances and manufactured goods. Utilizing structures like Alibaba and Global Sources streamlines the reference to capacity manufacturers.

Understanding Chinese markets includes staying knowledgeable about manufacturing companies' trends, regulatory requirements, and cultural nuances impacting commercial enterprise interactions. Also, one must know that China, alongside with the USA has been dominating the manufacturing industry for years, here is a diagram that will show how china succeeded to rise its manufacturing dominance over years since 2004 till late 2018 compared to the USA.

Reach to Sourcing companies or sourcing experts

Engaging with a devoted sourcing agent or a reputable sourcing enterprise is critical for overcoming supply chain demands and challenging situations and setting up a strong sourcing strategy. These specialists facilitate manufacturing unit inspections, oversee excellent examinations, and draft specified OEM contracts (original equipment manufacturing agreements. Sourcing agents play a critical role in ensuring producer compliance, coping with the cargo process, and growing contingency plans for capacity issues. Similarly, sourcing companies, performing as third-celebration entities, make appreciable contributions while offering organizations with cost-effective solutions and suitable production options.

DocShipper Advice : If you need the help of an expert in sourcing and procurement, just know that DocShipper offers a wide range of services related to sourcing. From sampling to quality control, passing through private labeling, standards compliance, supplier sourcing, and negotiation …. We will optimize your sourcing process from A to Z. Do you need more information? Contact our experts now !

Don’t overlook the power of Referrals

Leveraging referrals in the manufacturing field, mainly in the complicated Chinese market, is a game-changer. Recommendations must come from trustworthy, well-known or established companies in the manufacturing and production industries. Those referring systems or recommendations will help you get valuable insights that will comfort or question your decision of regarding your future manufacturing partner. Accessing a community of established companions via referral guarantees will help you sail peacefully through the production and manufacturing Chinese market. In a trust-centric environment, a reputable referral streamlines the search for a steady production partnership, supplying each warranty with efficiency.

Selecting the right fabricator or producer in China is important for a successful and green manufacturing process. To facilitate this decision, it’s vital to set up proper criteria. In this context, discover 5 key requirements, a good way to help you make knowledgeable selections, and foster a dependable partnership with a Chinese producer.

6 criteria to choose the right Chinese manufacturer

Capability

Assessing manufacturers’ abilities is crucial. Make use of platforms like Alibaba, Made in China, Global Sources, and DH Gate. Attend exchange gala's just like the Canton Fair or the ones prepared with the aid of HKTDC in Hong Kong. Those experts can provide you with valuable information and will help you assess the abilities of several producers available on the market.

Assessing a Chinese manufacturer involves researching their background, certifications, and production capacity. Evaluate their quality control, supply chain, and financial stability, while considering communication and flexibility. Visiting the facility and checking references will provide additional insights for a well-informed decision.

Experience

Evaluate if your contracted producer is specifically skilled in the industry/product that you are trying to source. Look to the experience and level of expertise, producers have accumulated over the years, in addition to the fact that they have or have not received the needed certifications and licenses to manufacture and produce goods in China.

Quality

What exceptional manipulation methods or quality assessment does the agreed producer follow? Do they have the applicable exceptional certification within the industry? Some exceptional certifications consist of ISO 9001 which suggests that the producer has an exceptional control device in place and has cleared the certification system in keeping with worldwide standards.

Price

In opting for a Chinese manufacturer, price is vital, highlighting the need for a balance between cost-effectiveness and product quality. Opting for the lowest price may be a compromise to well-created products or even lowering quality norms. Thus, a full assessment of pricing structures, including retired costs, is pivotal to ensuring that your choice aligns with budget constraints. While upholding ethics and a good reputation is important to ensure successful and sustainable manufacturing cooperation.

Capacity

Capacity refers to the volume of an order that the contracted manufacturer can handle and is a sign of their scaling-up capacities. Check if the supplier can address your requirements if your orders are veritably small or too big. Also check if they have the right equipment, storage space, warehouses, and technology to handle bulk orders or large volumes.

Equipment and Technology

The proper manufacturer is a person who makes use of the cutting-edge technologies and devices required to attain your requested quality, especially in cases where you require an excessive degree of customization. CNC machines, CAD/CAM or CAE engineering methods, robotics, and different state-of-the-art tools are just a small sample of the technologies a manufacturer or a producer in China may use. Many China primarily based total producers use excessive-stop generation.

Request For Proposal or quotes

Utilizing a Request for Proposal (RFP) or Request For Quotes(RFQ) is a strategic step in choosing a Chinese manufacturer. Those two formal requests for quotations allow you to discover specific proposals, give you complete insight into the Chinese producer's skills and pricing structures. By evaluating those offerings, you may make knowledgeable selections that align with your particular requirements. RFPs foster transparency and accountability, contributing to a successful and efficient partnership.

Negotiate prices and make your own MOQ

Prior to starting negotiations with a factory, it's vital to decide a viable minimum order quantity (MOQ). Orders falling beneath three hundred devices may not seize the factory's interest.

Once the MOQ is set, inquire approximately about the unit value in USD and calculate the value of the unit, then set the portions past this threshold. This proactive method aids in making plans for elevated manufacturing to fulfill growing demand. During negotiations, emphasize mutual satisfaction, and discover reduction possibilities within the factory. Fostering a partnership mindset is the key to successful negotiation. Finalize the settlement while each of the parties is satisfied with the negotiation.

Ask for a Product prototype or sample

Leveraging the skills of in-house Chinese manufacturers in terms of product improvement needs to be detailed and analyzed carefully. Professional product developers or prototyping experts, including designers, engineers, developers, and testers, give you the possibility to dive into the know-how and expertise of your partner

If you lack an in-house member to evaluate your product prototype or sample, you can decide to entrust your project to an external provider or sourcing agent like DocShipper. Ensuring good product layout and samples is essential to growing functional, visually appealing, and distinct merchandise. Prior to mass production, a thorough assessment of the prototype is imperative. In addition, to safeguard your interests, it is essential to confirm the manufacturer's registration of your product's intellectual property with each of China's intellectual property protection agencies and customs authorities.

Don’t skip the quality control

Quality control is a very important step in any production process, necessitating early discussions and requirement establishment. Whether self-production or operating with a manufacturing partner, defining the possible disorder charges and dictating corrective measures is essential from the start.

Post mass manufacturing, focuses on great management and then extends to engineers designing techniques to save you breakage all through the transport phase. Collaborating intently with logistics experts guarantees well-timed and damage-free shipments. Imposing some rules to monitor the quality control process will help you insure the smoothness of the production process and even the follow-up steps.

DocShipper Alert : Sourcing products from China can be challenging, especially when it comes to time-consuming procedures, a constrained pool of suppliers, and unexpected transport issues. However, DocShipper can assist you in revolutionizing the entire process by putting you directly in contact with trustworthy suppliers, discussing and negotiating your contract. If you need further details, complete our contact form; our services are only a call away!

What is not manufactured in China?

China has established itself as a worldwide production hub, generating a tremendous array of merchandise throughout numerous industries.

From electronics and textiles to equipment and customer goods, China has grown to be a production hub for lots of worldwide brands.

However, some products may not be produced or manufactured in China.

For example, we can name a few examples, including:

- High-give up luxurious goods,

- Precision scientific equipment,

- A few specialized aerospace additives are generally manufactured in areas that necessitate complex knowledge and sharp or strict standards.

- Additionally, certain meals and beverages, particularly those tied to specific areas or cultural traditions, can be better sourced from other countries than China.

Consequently, some experts in the sourcing field will definitely admit that China will never be good at producing Airplane engines…some computer chips, upscale treadmills, etc., and anything that is needed in small quantities and does not make sense to produce in China, since the demand is for small quantities and a high amount of precision. There are also two areas of advanced industrial processes that China still fails to master: Chip Making and Jet Turbine Blades.

While China covers an intensive variety of production, the manufacturing capacity of the Chinese market isn't without exception! Hence, some industries prioritize manufacturing in different areas to fulfill certain requirements.

Pros and cons of manufacturing in China

Embarking on manufacturing in China provides a myriad of possibilities and challenges. Understanding the pros and cons is crucial for groups thinking about this strategic move

| Advantages of of Chinese manufacturing | Disadvantages of Chinese manufacturing |

| Lower Production Costs | Communication and language difficulties |

|

|

| Market Growth | Quality control |

|

|

| High Output in Much Less Time | Intellectual asset infringements |

|

|

| Wide Variety of Providers to Pick From | High MOQ (Minimum Order Quantity) |

|

|

| Technological Advancements in China | Stigma of "Made in China" Products |

|

|

Docshipper Tip : If you find that the manufacturing process in China is too complex to handle and comprehend, you can entrust your sourcing project to DocShipper experts.Whether, you're searching for the right suppliers or manufacturers in China, or just trying to grasp a better comprehension of the specificities of the Chinese market. We can help you just feel free to contact us or call us now!

Mistakes to avoid while manufacturing in China

Knowing the best tips regarding manufacturing Chinese products is certainly a must in order to succeed in this challenge. However, discovering mistakes and traps is also so important. So here are some errors you must avoid :

- Not Having a Firm Quotable Specification : make sure your specifications are well-prepared and defined, before even starting to search for a manufacturer or getting an agreement with him.

Having a firm, quotable specification from the start guarantees reasonable and comparative charges. While any adjustments in the course of the production process may generate extra fees and charges that may be difficult to handle. If you find yourself in this complicated situation, an expert can assist you in monitoring such difficult adjustments.

- Thoroughly check the background of your producer: investigate the manufacturer's history, consumer relationships, and integrity to make sure your products will be well maintained. Establishing, monitoring, and retaining a sturdy evaluation and analysis is vital to preventing bad surprises.

- Will Your Intellectual Property Stay Protected? Manufacturers, leveraging their expertise, may also suggest some functions or features to beautify the product design. However, these changes can bring unexpected risks, possibly altering properties and raising questions about factories declaring patentable elements. Vigilance and criminal safeguards are essential to meet these jurisdictional challenges.

- Keep Revisions to a minimum: minimize revisions during quotation and preliminary pilot build ranges to limit expenses and keep the factory's attention. Longer schedules or incessant rework can strain relations with the producer, leading to production delays or increased expenditure. Keeping revisions to a minimum is essential for a clean, environmentally friendly manufacturing process.

DocShipper Advice: Avoid paying a complete 100% deposit for orders from China, especially while dealing with new molds or examining the product. This precaution prevents potential issues, which includes factories with financial problems or the risk of the supplier disappearing after receiving the payment. Trust DocShipper to guide you through every step of your manufacturing process in China. Contact us for more information.

How to maintain a good relationship with a Chinese manufacturer

Developing and keeping an excellent relationship with your producer in China may be pretty crucial for the success of your business. If you've found a good partner that works for you and your company, you must aim to collaborate with them for as long as possible so that you can create a strong bond with them.

You can try this by:

- Maintaining effective communication with a worldwide producer, in particular in China, is essential for a successful relationship

- Respecting cultural differences is important in Chinese companies's interactions.

Avoiding practices such as prolonged joint meetings, and emphasizing private and professional relationships, is in line with the values of the Chinese way of life and encourages fruitful exchanges with manufacturers.

- Pay your partners on time: pay your manufacturers and suppliers on time, and in case you can't do it, make sure your producer understands your motives properly in advance. Don't forget that this is also a business venture, and draw up an agreement specifying the pricing conditions so that you can both respect it.

- Maintaining honesty and transparency with producers: concerning your needs is essential for a clean and trustworthy relationship. Preventive communication of expectations helps avoid problems and risks of error, so the use of equipment such as supplier relationship management solutions ensures centralized communication for successful collaboration.

Conclusion

In conclusion, effectively manufacturing a product in China in 2024 calls for a well-taught method and a proper knowledge of your needs, as well as the specificities of the Chinese manufacturing market. By following those hints and taking a proactive approach, you can optimize your chances of getting a smooth manufacturing process while producing your goods in China. For more requests, feel free to contact Docshipper sourcing experts, who will be thrilled to guide you through the whole manufacturing process.

FAQ | How to Manufacture a Product in China? your survival guide for 2024

What is the diverse range of products that China manufactures?

China dominates the global manufacturing market; it leads the market in various industries. Clothing and Fashion Accessories, Tech Accessories and Gadgmarketets, Makeup and Cosmetics;Phones and Computers, Children’s Toys, Pet Supplies and Outdoor and Travel Products

what are Chinese manufacturing regions ?

China hosts several major production hubs, each focusing on diverse industries: Shanghai:Located on the central coast, Shanghai is known for textiles, electronics, automobiles, communication equipment, and steel manufacturing. Guangzhou:Located on the central coast, Shanghai is known for textiles, electronics, automobiles, communication equipment, and steel manufacturing. Shenzhen: Recognized as the global hub for electronics production. Ningbo: Experiencing rapid boom because of its proximity to Shanghai. It is known for producing textiles, garments, electric appliances, iron, steel, and biological medicine

How do I choose the right wholesale marketplace for my product category?

Selecting the precise wholesale market depends on your product category. Research is key when it comes to situating yourself and your offer. Once you do it properly you’ll get information related to location, reputation, the form of suppliers, customization options, quality control, and proximity to transportation hubs. Each marketplace focuses on different products, so it's crucial to discover the one that align with your sourcing needs

Why is it important to maintain a good relationship with Chinese manufacturers?

Maintaining a great relationship with a Chinese manufacturer is essential for effective communication, trust-building, and fruitful achievements, which happens to be essential for to your manufacturing endeavours

DocShipper info: Do you like our article today? For your business interest, you may like the following useful articles :

DocShipper Sourcing | Procurement - Quality control - Logistics

Alibaba, Dhgate, made-in-china... Many know of websites to get supplies in Asia, but how many have come across a scam ?! It is very risky to pay an Asian supplier halfway around the world based only on promises! DocShipper offers you complete procurement services integrating logistics needs: purchasing, quality control, customization, licensing, transport...

Communication is important, which is why we strive to discuss in the most suitable way for you!